Working principle of quartz sand rotary kiln:

The rotary kiln adopts a ** inclined rotating cylinder design. The material (quartz sand) enters from the high end (feeding end) and moves to the low end (discharging end) under the action of gravity and the rotation of the cylinder, while undergoing high-temperature calcination. The main processes include:

Preheating zone: 200-800°C, evaporating water and preliminarily decomposing organic matter.

Calcination zone: 800-1300°C, removing impurities such as iron and aluminum, and improving the purity of SiO₂.

Cooling zone: After discharging, the material is cooled by a cooler to avoid the crystal transformation of quartz sand.

Key features:

Rotation design: ensure that the material is heated evenly to avoid agglomeration.

High temperature control: the combustion temperature can be adjusted to meet different purity requirements.

Continuous production: automatic feeding, calcination, and discharging, with high efficiency.

The main structure of quartz sand rotary kiln:

part | Functional Description |

|---|---|

Kiln Shell | Made of high temperature resistant steel plate, lined with refractory materials (such as high alumina bricks) |

Riding Ring & Support Rollers | Support the kiln body and make it rotate smoothly |

Drive System | Motor + reducer + gear drive, control speed (usually 0.5–5 RPM) |

Burner | Provide high temperature heat source (gas, pulverized coal, fuel oil, etc.) |

Sealing System | Prevent heat loss and outside air from entering |

Dust Removal & Exhaust Gas Treatment | Reduce environmental pollution and comply with environmental standards |

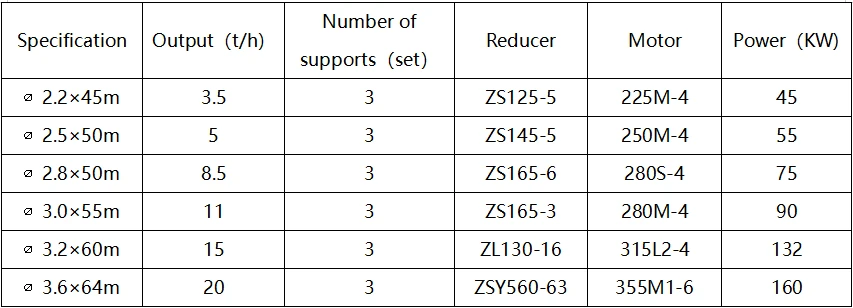

Technical parameters of quartz sand rotary kiln:

Application fields of quartz sand rotary kiln:

Photovoltaic industry: production of high-purity quartz sand (SiO₂≥99.9%) for solar silicon wafers.

Electronics industry: manufacturing semiconductor-grade quartz crucibles and optical fiber preforms.

Foundry industry: calcining casting sand to improve fire resistance.

Chemical filler: modified quartz sand is used for coatings, rubber, and plastic reinforcement.

Glass industry: as pretreatment equipment for glass raw materials.