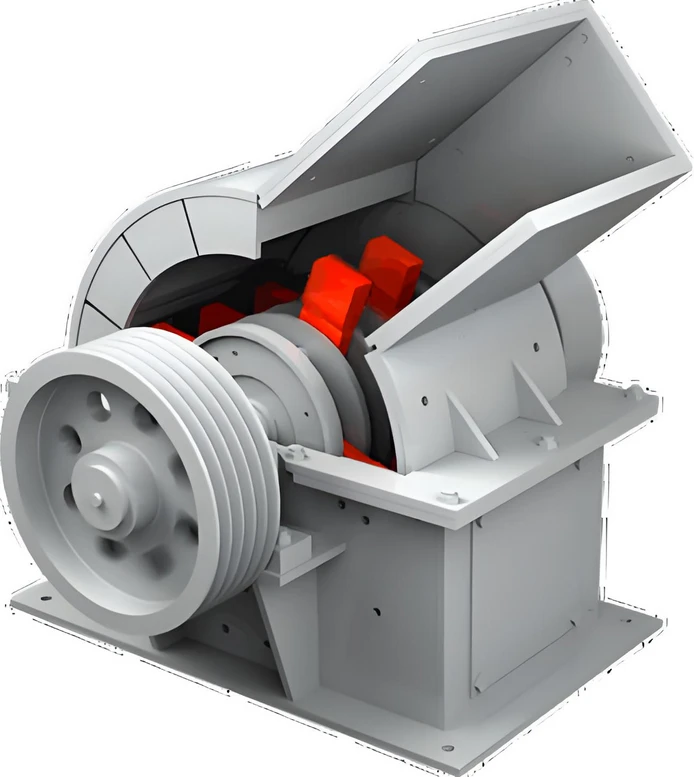

Main structure

1. Casing: including upper and lower casings, usually welded by steel plates, with wear-resistant lining inside.

2. Rotor: composed of main shaft, hammer plate and hammer head, it is the core component of hammer crusher.

3. Hammer head: installed on the hammer plate, usually made of high manganese steel or other wear-resistant materials.

4. Screen plate: located under the rotor, controlling the particle size of the discharge.

5. Transmission device: including motor, pulley and V-belt, used to drive the rotor to rotate.

Working principle

The material enters the crushing chamber from the feed port, and the high-speed rotating hammer head impacts and shears the material to break it. The crushed material is discharged through the sieve holes of the sieve plate, and the material that does not meet the particle size requirements continues to be impacted by the hammer head until it meets the requirements.

Advantages

1. Large crushing ratio: usually up to 10-25, suitable for coarse crushing and medium crushing.

2. Simple structure: easy to manufacture and maintain.

3. High production efficiency: low unit energy consumption and high output.

4. Strong adaptability: can handle materials of various hardness and humidity.

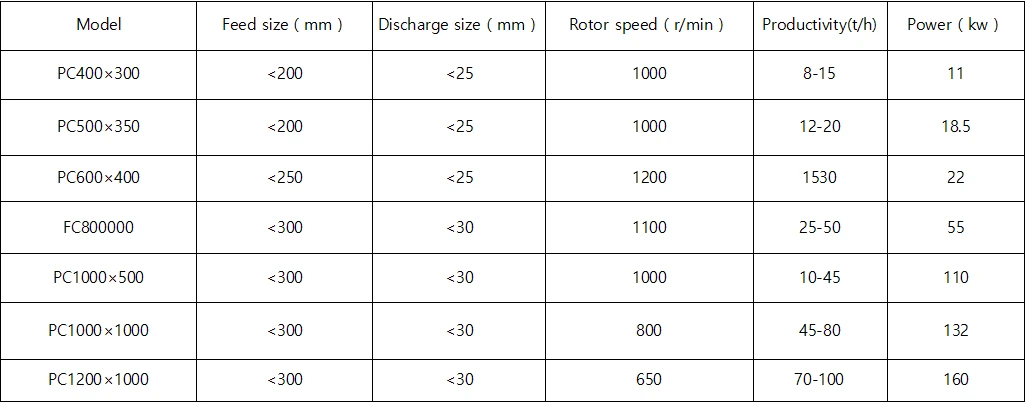

Technical Parameters

Disadvantages

1. The hammer head wears quickly: it needs to be replaced regularly, which increases maintenance costs.

2. High noise and dust: corresponding environmental protection measures need to be taken.

3. Not suitable for crushing sticky materials: easy to block the screen plate.

Application areas

1. Mining: used for crushing limestone, gypsum, coal, etc.

2. Building materials: used for crushing cement clinker, sand and gravel, etc.

3. Chemical industry: used for crushing fertilizers, salt, etc.

4. Metallurgy: used for crushing ore, slag, etc.

Maintenance and care

1. Check the hammer head wear regularly and replace it in time.

2. Check whether the screen plate is blocked and clean it in time.

3. Lubricate the bearings to ensure the normal operation of the transmission device.

4. Check the fasteners regularly to prevent loosening.