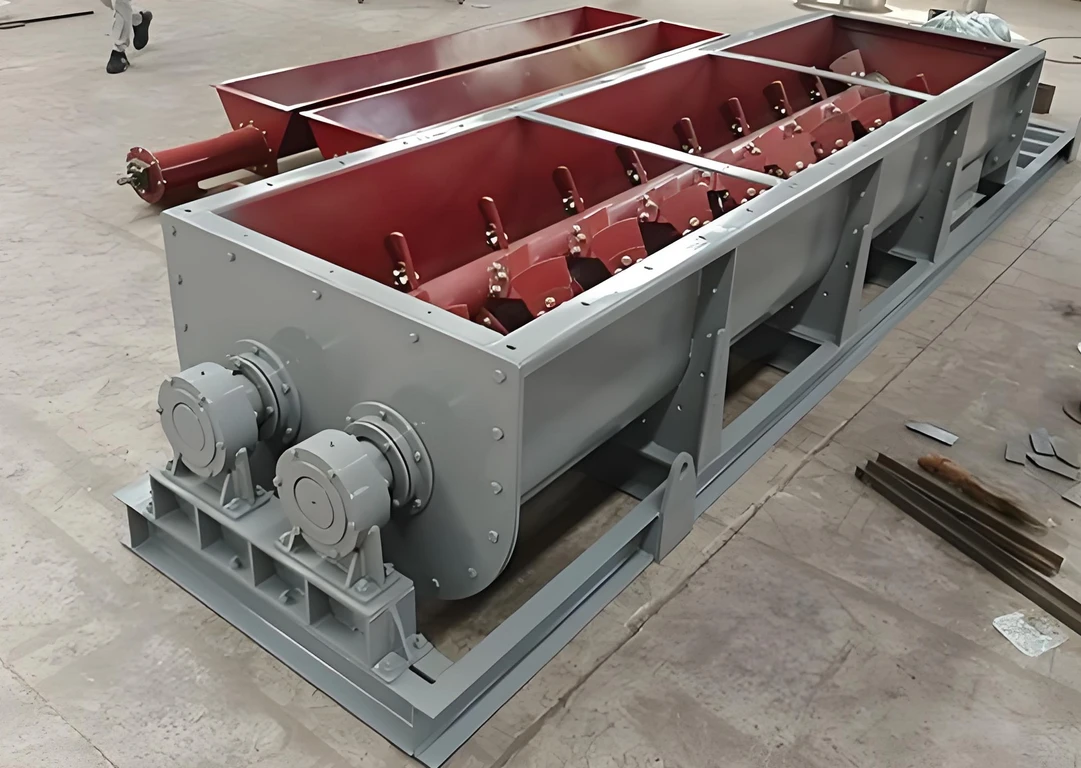

Main features:

1. Efficient mixing: The dual-axis design allows the material to be subjected to multi-directional forces during the mixing process, making the mixing more uniform.

2. Strong adaptability: It can handle materials of different viscosities and densities, and is suitable for various forms such as dry powder, granules, and slurries.

3. Strong structure: It is usually made of wear-resistant materials and is suitable for long-term continuous work.

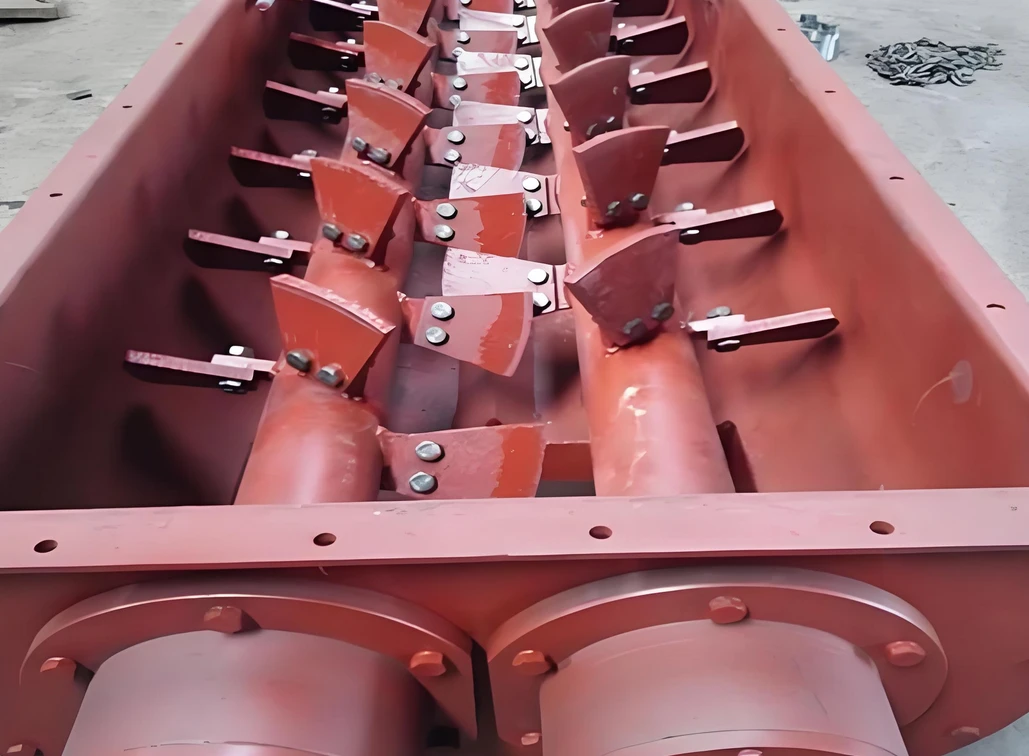

4. Customizable: The mixing blades and speed can be adjusted according to specific needs to adapt to different process requirements.

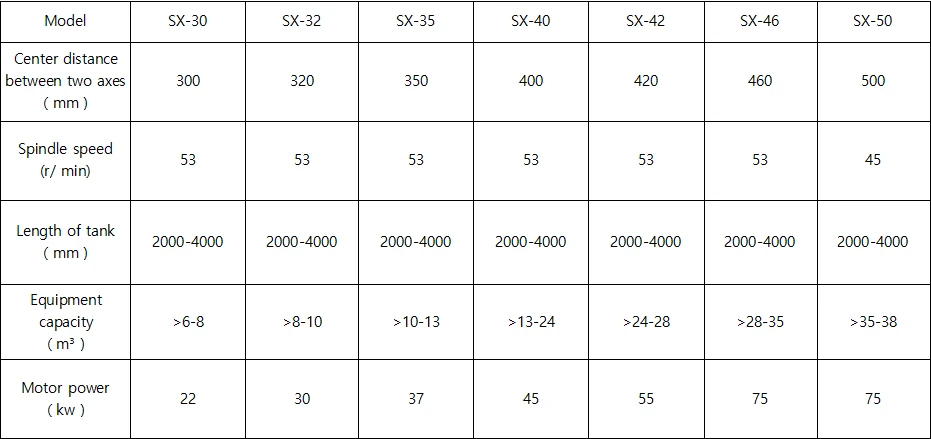

Technical Parameters:

Application areas:

Building materials: used for mixing cement, mortar, concrete, etc.

Chemical industry: mixing chemical raw materials, pigments, coatings, etc.

Food industry: mixing flour, seasonings, food additives, etc.

Environmental protection field: processing sludge, solid waste, etc.

Working principle:

The dual-axis mixer drives the two mixing shafts to rotate synchronously or asynchronously through the motor, and the mixing blades cut, squeeze, and flip the materials to achieve uniform mixing. The mixing speed and direction can be adjusted according to the characteristics of the material.

Selection considerations:

1. Material characteristics: Select the appropriate mixer model based on the material's viscosity, density, particle size, etc.

2. Production capacity: Select equipment with appropriate capacity and power based on production needs.

3. Material requirements: Select appropriate materials (such as stainless steel, carbon steel, etc.) based on the material's corrosiveness, wear resistance, etc.