Working Principle

The double roller crusher is mainly composed of two parallel rollers with a certain gap between them. The material enters from the top, and as the rollers rotate, the material is squeezed, crushed, and finally discharged from the bottom. The speed and gap of the rollers can be adjusted according to the material properties and crushing requirements.

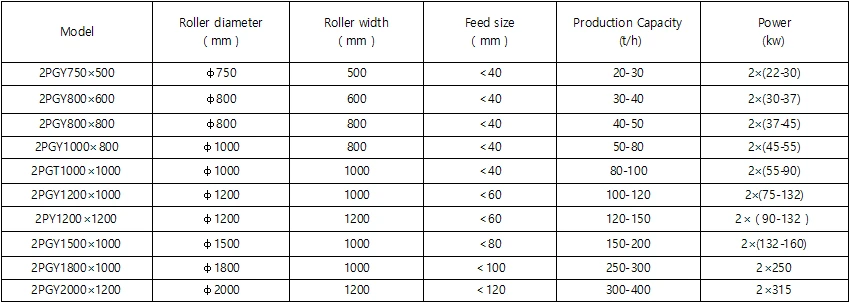

Hydraulic Roll Crusher Parameters

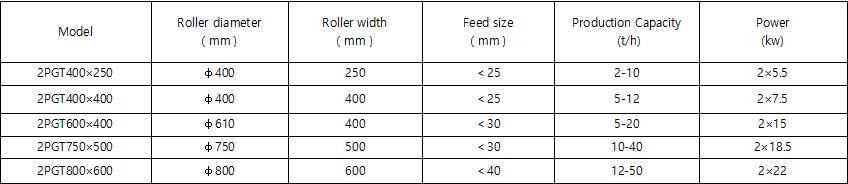

Spring Roller Crusher Parameters

Main structure

1. Roller: usually made of highly wear-resistant material, the surface can be smooth or with tooth grooves to enhance the crushing effect.

2. Transmission device: including motor, reducer, etc., used to drive the roller to rotate.

3. Adjustment device: used to adjust the gap between the rollers and control the crushing particle size.

4. Frame: Support the entire equipment to ensure stable operation.

Advantages

Simple structure: easy to maintain and operate.

Large crushing ratio: able to handle larger pieces of material.

Uniform particle size: the material after crushing has uniform particle size, suitable for subsequent processing.

Application field

Mining: crushing ore, coal, etc.

Building materials: crushing limestone, cement clinker, etc.

Chemical industry: crushing chemical raw materials.

Precautions

Regular maintenance: Check the roller wear and replace it in time.

Material hardness: Avoid crushing too hard materials to avoid damage to the equipment.

Safe operation: Ensure the safety of personnel during equipment operation to avoid accidents.

Roller crushers play an important role in industrial production. Choosing the right model and correct operation can significantly improve production efficiency and product quality.