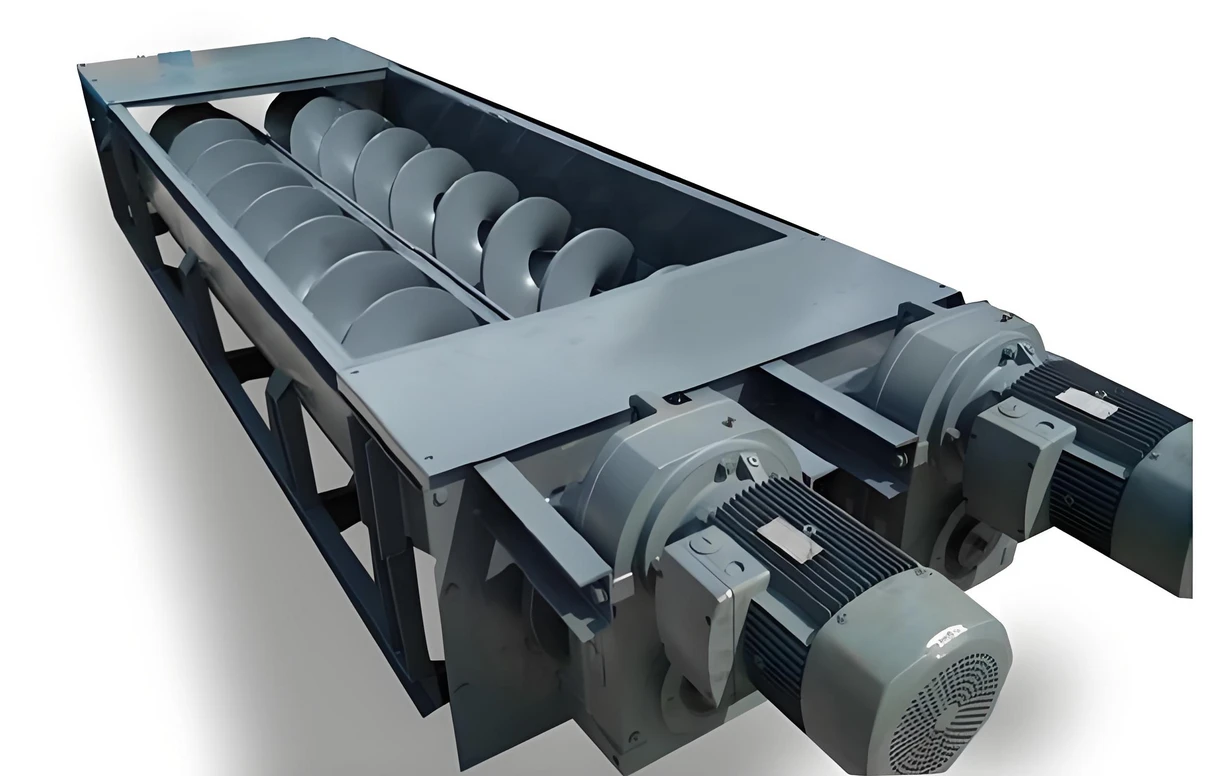

Main components

Scraper chain: It consists of a scraper and a chain. The scraper is responsible for pushing the material, and the chain provides traction.

Trough: A closed or semi-closed shell for accommodating materials and scraper chains.

Driving device: It includes a motor, a reducer, and a driving sprocket, which provide power to move the scraper chain.

Tensioning device: Maintains the proper tension of the chain to prevent the chain from loosening or slipping.

Feed port and discharge port: The entrance and exit of the material.

Guide device: Ensures that the scraper chain runs smoothly in the trough.

Working principle

The scraper conveyor drives the scraper chain to circulate in the trough through the driving sprocket. The material enters the trough from the feed port, is pushed by the scraper and transported to the discharge port. The scraper chain is supported by the guide rail at the bottom of the trough during the return journey, forming a closed circulation system.

Advantages

Good airtightness: Suitable for conveying materials with large dust, easy to fly or easy to pollute.

Strong adaptability: It can be used for horizontal, inclined or vertical transportation.

Strong structure: suitable for conveying heavy or abrasive materials.

Long conveying distance: Compared with screw conveyors, scraper conveyors can be used for longer conveying distances.

Disadvantages

High energy consumption: Due to the large friction resistance, the energy consumption is relatively high.

Large wear: scrapers and chains are easy to wear and need to be replaced regularly.

Noise: Loud noise may be generated during operation.

Application scenarios

Coal industry: used for underground or ground coal transportation.

Mining industry: conveying ore, slag, etc.

Chemical industry: conveying powdered or granular chemical raw materials.

Grain industry: conveying grain, feed, etc.

Common types

Horizontal scraper conveyor: used for horizontal or small angle inclined transportation.

Vertical scraper conveyor: used for vertical or large angle inclined transportation.

Buried scraper conveyor: The scraper chain is completely buried in the material, suitable for closed transportation.

Ordinary scraper conveyor: The scraper chain is partially exposed, suitable for general material transportation.

Common problems and solutions

Chain breakage: Check the chain wear and replace it in time.

Scraper wear: Check the scraper status regularly and replace the severely worn scraper.

Material blockage: Adjust the feed rate and clean the blocked parts.

Excessive noise: Check the chain tension and lubricate the chain and sprocket.

Maintenance

Check the scraper and chain wear regularly.

Lubricate the chain and drive device.

Clean the accumulated material in the tank.

Check the tensioner to ensure the chain tension is appropriate.