Usage and Application

CZS High-efficient Cone Crusher isa high-performance model optimized andimproved on the basis of PY Series SpringCone Crusher.It is widely used forsecondary and fine crushing in the fieldsof mining, building materials, metallurgyand so on,It can crush materials withmiddle and high hardness, such as metalore,basalt,granite.limestonecobblestone,sandstoneand so on.

Working Principle

1. Feed: The material enters the crushing chamber from the feed inlet.

2. Laminated crushing: The material is subjected to compression and impact from the moving cone and fixed cone inside the crushing chamber, achieving laminated crushing.

3. Discharge: The crushed material is discharged through the discharge port, and the particle size is controlled by the gap between the discharge ports.

Features

1.Customers can choose suitablecrushing cavity according to the materialfeature, finished product fineness andparticle size requirement.

2.Unique dustproof and sealingstructure extend cycle oflubricantsreplacement and spare parts service life.

3. The key parts are made of specialmaterials,which support the strongcrushing.

4. With long crushing arm, big stoke.

strong crushing, and high capacity.

5.Adopting hydraulic chambercleaning system,easyoperation,andreduce machine downtime.

6. With reliable performance, lowinvestment cost, and long service life ofquick-wear parts.

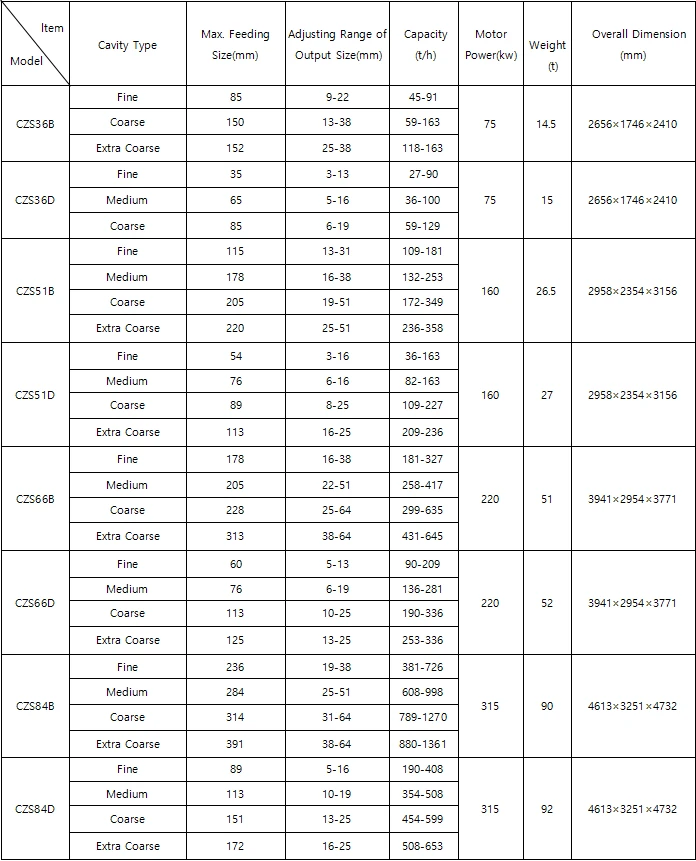

Main Specifications

Maintenance

1. Regular lubrication: Regularly lubricate moving parts such as bearings and eccentric shafts to reduce wear.

2. Check the lining plate: Regularly inspect the wear of the dynamic cone and fixed cone lining plates and replace them in a timely manner.

3. Tighten bolts: Regularly check and tighten the bolts of various parts of the equipment to prevent loosening.

4. Cleaning the crushing chamber: Regularly clean the residual materials inside the crushing chamber to prevent blockage.

5. Electrical inspection: Regularly inspect the electrical system to ensure safe operation of the equipment.

Common faults and solutions

1. Lining wear: Replace with a new lining.

2. Overheating of bearings: Check the lubrication condition and replenish or replace the lubricating oil.

3. Abnormal equipment vibration: Check if the bolts are loose and adjust the equipment balance.

4. Uneven discharge particle size: Adjust the clearance between the discharge ports or check the wear of the lining plate.