Product Introduction:

Kaolin is white and very fine, also known as dolomite. It has good plasticity and wear resistance and is widely used in papermaking, ceramics, wear-resistant materials, textiles, chemicals, building materials and other industries.

Kaolin grinding mill is mainly used to produce kaolin powder. It is a new type of grinding mill that replaces ball mill to process kaolin powder. Compared with ball mill, kaolin grinding mill is more convenient and simple to operate, easy to use, and easy to replace accessories. It can meet the high demand for kaolin in large projects and has many advantages such as good product particle shape, stable performance and high production capacity.

Structural composition

The kaolin mill has a simple structure, mainly composed of motor, V-belt, blade, spring positioning sleeve, spring, spring seat, roller grinding shaft, grinding ring, scraper and other parts. It can also be equipped with crusher, analyzer, electromagnetic vibration feeder and other equipment as needed to form a grinding production line to complete the required grinding operation.

Performance advantages:

1. The whole machine is a three-dimensional structure, with a small footprint and strong system. From block material to finished powder, it is completed by an independent production system.

2. Advanced dust removal technology is adopted, the on-site dust removal effect is good, less dust, low noise, and meets environmental protection requirements.

3. The degree of automation is very high, and the centralized control ability of the electrical system is very strong. It can basically realize unmanned operation to complete the operation well, reducing the labor intensity of manual labor.

4. Long service life, all parts are made of highly wear-resistant materials, with strong wear and impact resistance, reducing the friction of parts and reducing maintenance costs.

Working Principle:

When the kaolin Raymond mill is working, the kaolin to be crushed is added into the machine from the feed hopper on the side of the machine cover. The grinding roller device hanging on the main machine plum blossom frame revolves around the vertical axis and rotates itself. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring, so that the scraper scoops up the material and sends it between the grinding roller and the grinding ring. The purpose of crushing the material is achieved due to the rolling and crushing of the grinding roller. Qualified materials will enter the cyclone separator for separation and collection through the analyzer, and unqualified materials will return to the grinding chamber to continue the above actions until the kaolin grinding work is completed.

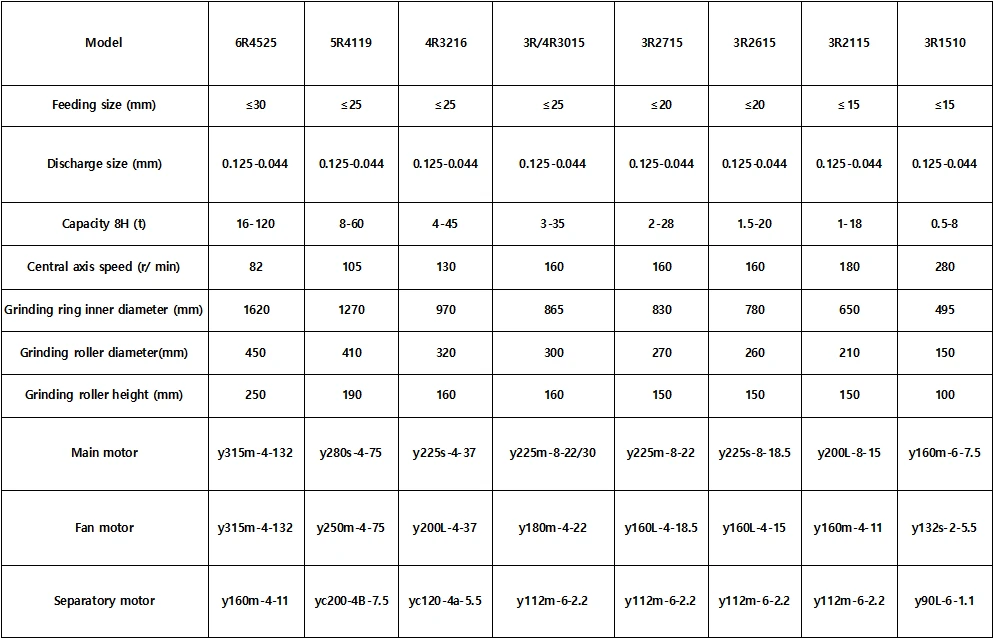

Technical Parameters: