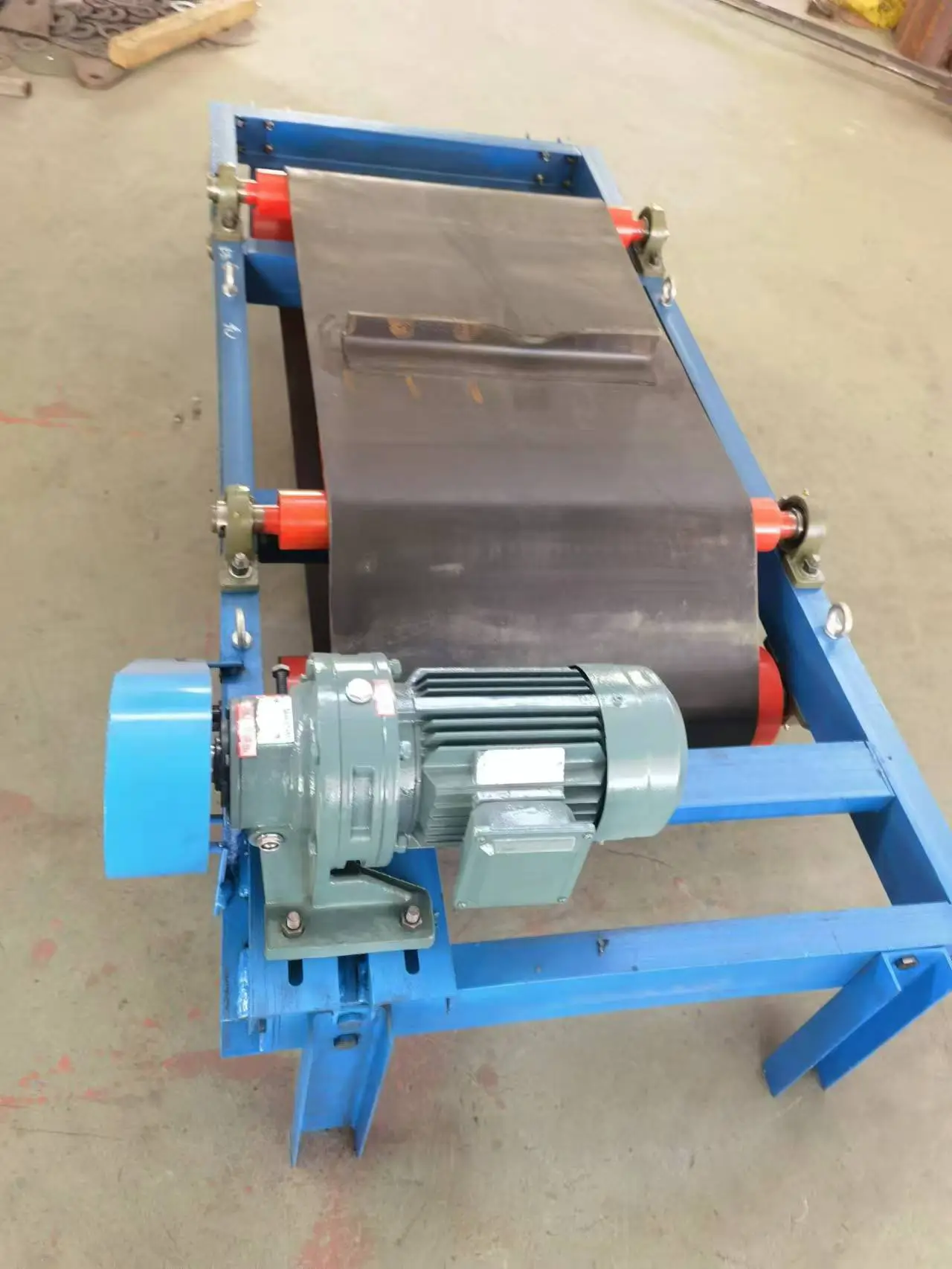

Composition of belt type iron remover

1. Magnetic system:

The core component, usually composed of high-performance permanent magnetic materials (such as neodymium iron boron) or electromagnets, is used to generate a strong magnetic field.

The magnetic system is designed as an open structure to facilitate the adsorption of ferromagnetic impurities.

2. Drive device:

- Includes motor, reducer and drive roller to drive the iron removal belt to run.

3. Iron removal belt:

Used to carry the adsorbed ferromagnetic impurities and transport them to the designated location.

The belt material is usually wear-resistant and high-temperature resistant rubber or polyurethane.

4. Iron removal device:

Used to remove ferromagnetic impurities adsorbed on the belt, usually using a scraper or vibration device.

5. Frame:

The frame structure that supports the entire equipment is usually made of steel and has sufficient strength and stability.

6. Control system:

Used to control the operation of the equipment, including start, stop, speed regulation and other functions.

Working Principle

The working principle of the belt type iron remover is based on magnetic separation technology:

1. When the material passes through the belt type iron remover, the ferromagnetic impurities are adsorbed onto the iron removal belt under the action of the magnetic field.

2. The iron removal belt runs continuously under the action of the driving device, and transports the adsorbed ferromagnetic impurities to the iron unloading device.

3. The iron unloading device removes the ferromagnetic impurities from the belt and drops them into the iron collection box or the designated location.

4. The cleaned material continues to be transported to the downstream equipment.

Features of the belt type iron remover

1. Efficient iron removal:

The high-performance magnetic system can effectively remove ferromagnetic impurities in the material.

2. Continuous operation:

The iron removal belt runs continuously to achieve uninterrupted iron removal.

3. High degree of automation:

It can be linked with the conveying system to achieve automatic control.

4. Wide range of applications:

It is suitable for iron removal of various materials such as particles, powders, and blocks.

5. Convenient maintenance:

The structure is simple and easy to install and maintain.

Maintenance and care

1. Check the magnetic system regularly:

Check whether the magnetic field strength of the magnetic system is normal, and replace the aged magnetic blocks in time.

2. Clean the equipment:

Clean the dust and debris on the iron removal belt and the iron unloading device regularly to prevent affecting the iron removal effect.

3. Check the belt:

Check the tension and wear of the belt, and adjust or replace it in time.

4. Lubrication and maintenance:

Lubricate the drive device and roller regularly to reduce wear.

Common problems and solutions

1. Poor iron removal effect:

Possible reasons: insufficient magnetic field strength, too fast belt speed.

Solution: Check the magnetic system and adjust the belt speed.

2. Belt deviation:

Possible reasons: uneven belt tension, improper roller installation.

Solution: adjust the belt tension and correct the roller position.

3. Incomplete iron unloading:

Possible reasons: failure of the iron unloading device, impurities adhering to the belt surface.

Solution: Check the iron unloading device and clean the belt surface.