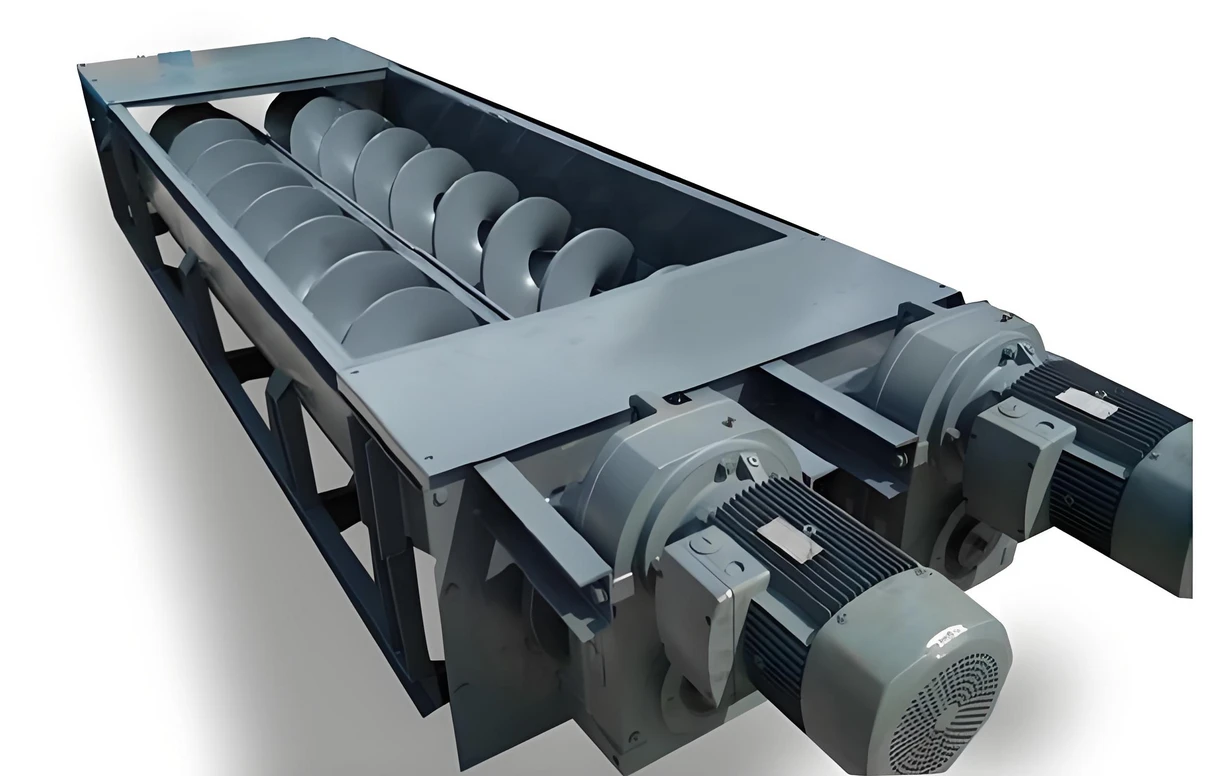

Main components

Spiral blade: the core component, which pushes the material forward by rotating. The blade can be solid, belt or paddle.

Trough or pipe: the shell that holds the material and spiral blade, usually a U-shaped trough or round tube.

Drive device: including motor, reducer and coupling, providing power to rotate the spiral shaft.

Feed port and discharge port: the inlet and outlet of the material.

Bearing: support the spiral shaft to reduce friction.

Suspension bearing: used to support the spiral shaft during long-distance transportation.

Working principle

The screw conveyor drives the spiral shaft to rotate through the motor, and the spiral blade pushes the material from the feed port to the discharge port. The movement of the material is similar to the movement of the nut on the screw, and the material is continuously transported as the spiral blade rotates.

Advantages

Simple structure: compact equipment, small footprint.

Good sealing: suitable for conveying dusty, easy to fly or easy to pollute materials.

Multifunctional: can be used for horizontal, inclined or vertical transportation.

Easy to control: the conveying volume can be controlled by adjusting the speed or feed volume.

Disadvantages

Limited conveying distance: generally suitable for short-distance conveying (usually not more than 30 meters).

Materials are easy to wear: fragile or sticky materials may cause wear or blockage.

High energy consumption: compared with belt conveyors, energy consumption is higher.

Application scenarios

Grain processing: conveying grains, flour, feed, etc.

Chemical industry: conveying powdered and granular chemical raw materials.

Building materials industry: conveying cement, lime, sand and gravel, etc.

Environmental protection industry: conveying sludge, waste, etc.

Common types

Horizontal screw conveyor: used for horizontal or small-angle inclined conveying.

Vertical screw conveyor: used for vertical or large-angle inclined conveying.

Bendable screw conveyor: suitable for occasions requiring curved paths.

Shaftless screw conveyor: suitable for materials with high viscosity and easy entanglement.

Common problems and solutions

Material blockage: adjust the speed, clean the blocked parts, or replace the appropriate spiral blades.

Bearing wear: lubricate regularly and check the bearing status.

Excessive noise: Check if the screw shaft is bent or the bearing is damaged.