Function

The main functions of the rotary kiln burner include:

Provide heat source: generate high temperature by burning fuel to meet the needs of material calcination or chemical reaction.

Control temperature: adjust the flame shape and temperature distribution to ensure uniform temperature in the kiln.

Optimize combustion: improve fuel utilization, reduce energy consumption and emissions.

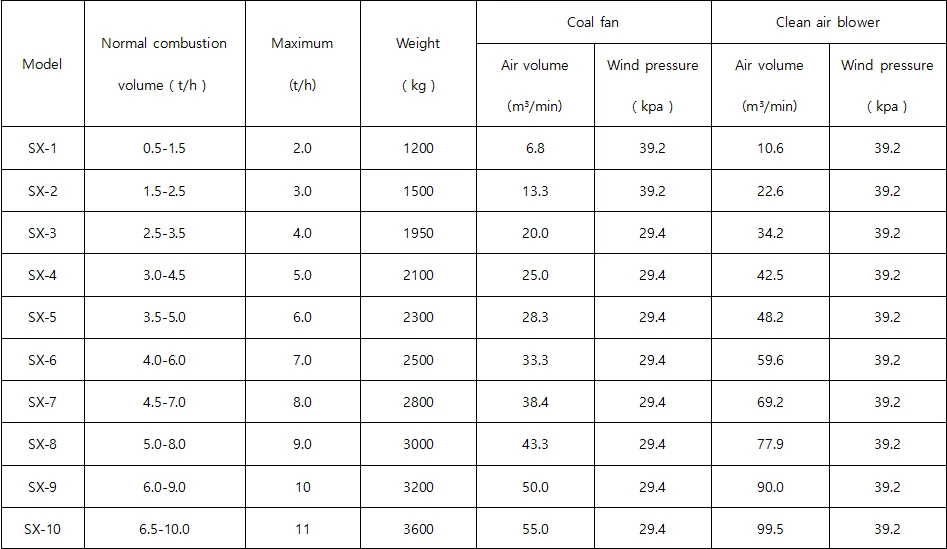

Technical Parameters

Type

According to different fuels and structures, rotary kiln burners can be divided into:

Pulverized coal burner: uses pulverized coal as fuel, commonly used in cement kilns.

Gas burner: uses gas fuels such as natural gas and liquefied gas, suitable for occasions with high environmental protection requirements.

Oil burner: uses heavy oil and diesel as fuel, suitable for specific industrial kilns.

Multi-fuel burner: can use multiple fuels at the same time to improve flexibility.

Structure

The rotary kiln burner usually includes the following parts:

Fuel nozzle: sprays fuel to affect the flame shape and combustion efficiency.

Air channel: provides combustion air, which is divided into primary air and secondary air.

Ignition device: used to ignite fuel.

Control system: adjusts the fuel and air flow to control the combustion process.

Working principle

When the burner is working, the fuel is sprayed into the kiln through the nozzle, mixed with air and ignited to form a high-temperature flame. The control system adjusts the amount of fuel and air according to the temperature in the kiln to ensure stable combustion.

Application areas

Rotary kiln burners are widely used in:

Cement industry: for clinker calcination.

Metallurgical industry: for ore roasting and metal smelting.

Chemical industry: for material drying and chemical reaction.

Environmental protection industry: for waste treatment.

Maintenance and maintenance

To ensure the normal operation of the burner, it is necessary to regularly:

Clean the nozzle: prevent blockage.

Check the ignition device: ensure normal ignition.

Monitor the combustion situation: optimize the combustion efficiency.

Replace worn parts: extend the life of the equipment.

Development trend

The future development direction of rotary kiln burners includes:

High efficiency and energy saving: improve combustion efficiency and reduce energy consumption.

Low emission: reduce pollutant emissions and meet environmental protection requirements.

Intelligent: introduce automatic control system to improve operation accuracy.