How it works:

The compound crusher has a large crushing ratio, a wide range of crushed moisture content, and is ideal for processing materials with high moisture content. The discharge particle size can be adjusted arbitrarily, and there is no screen bar setting. Materials with a large amount of sediment will not be blocked, and unbreakable materials can be automatically discharged into the machine body without causing damage to the equipment. The compound crusher has high production efficiency, unique structure, stable operation, low noise, and convenient maintenance. The damaged parts can be easily replaced by opening the working chamber door.

After the material enters the crushing chamber, it is hit by the high-speed rotating hammer and projected onto the impact plate for secondary crushing. The rotor is the core component of high-speed rotation, which drives the hammer to impact the material (the speed is usually 500-1500rpm). The hammer is a wear-resistant component that directly hits the material, and the material is mostly high-chromium alloy (Cr20~Cr26). The material collides repeatedly between the hammer and the screen plate, and is discharged from the bottom after reaching the particle size.

The rotor diameter and length determine the processing capacity and crushing efficiency. The feed size is usually ≤120mm (too large will reduce the efficiency), and the discharge is generally 3-5mm. The dryness and wetness of the material should also be considered during the production process.

Performance characteristics:

High efficiency and energy saving

Compound crushing method (impact + grinding) improves crushing efficiency and has low energy consumption.

Adjustable particle size

Control the discharge particle size (usually ≤5mm) by adjusting the rotor speed, the gap between the impact plate or the aperture of the screen plate.

Strong adaptability

Can handle medium and high hardness materials (such as limestone, coal gangue, gypsum, etc.), with good adaptability to moisture content.

Easy maintenance

Key components (such as hammer head and impact plate) are made of wear-resistant materials and are easy to replace.

Application areas:

Mining: Crushing iron ore, gold ore, etc.

Building materials: Cement raw materials, clinker, construction waste recycling.

Chemicals/metallurgy: Processing of raw materials such as coal gangue and phosphate rock.

Selection points:

Material characteristics: hardness, humidity, feed size (usually ≤50mm).

Capacity requirements: small machine (5-100t/h), large machine can reach more than 300t/h.

Discharging requirements: fine crushing (≤3mm) or medium crushing (5-10mm).

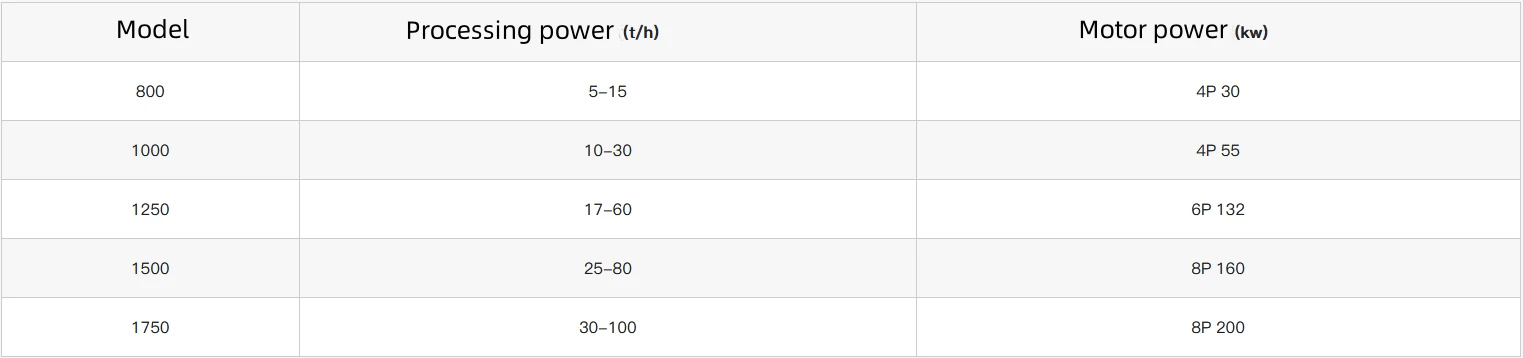

Technical Parameters:

Development trend:

Intelligent: Install sensors to monitor the operating status in real time.

Environmental protection: Optimize the sealing design to reduce dust spillage.

Multifunctional: Adapt to more material types (such as construction waste recycling).