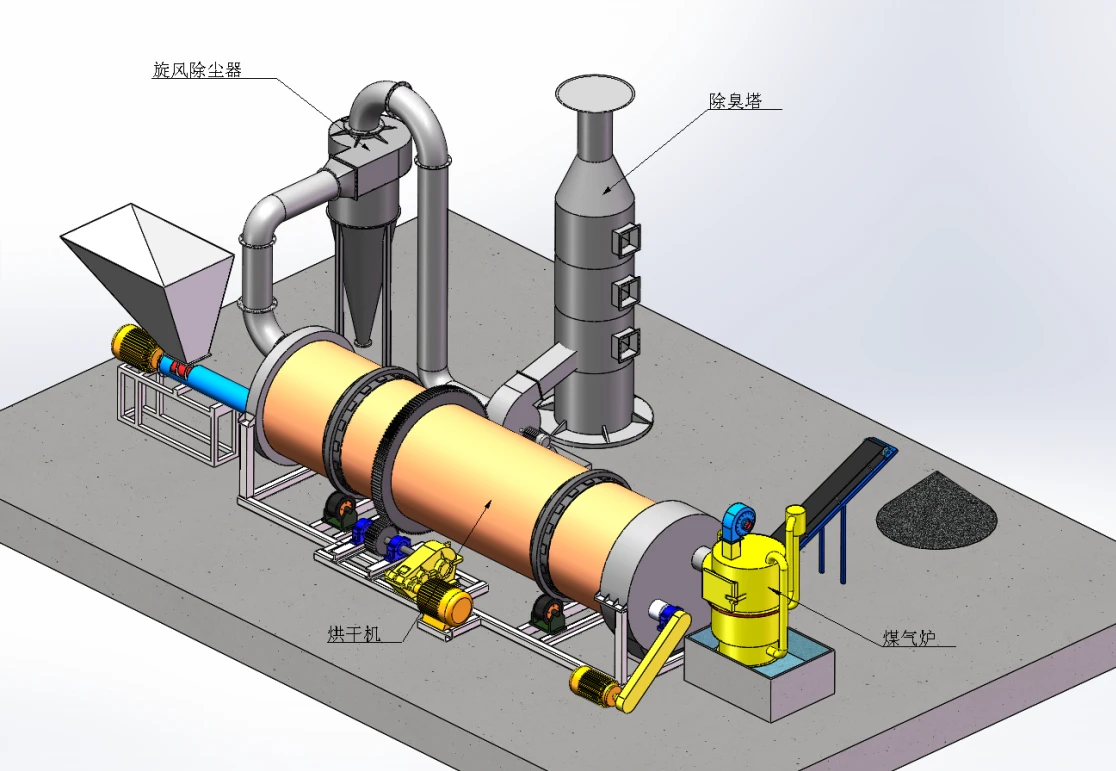

Mechanical structure and working principle:

The fertilizer dryer can directly dry livestock manure with a moisture content of up to 70%-80% to a safe storage moisture content of 13% at one time. The entire process is carried out in a closed system, thereby reducing the pollution to the environment during the drying process. The equipment is mainly composed of a heat source, a loader, a feeder, a rotary drum, a discharging machine, a material crushing device, an induced draft fan, a discharger and a distribution cabinet; after the dehydrated wet material is added to the dryer, the material is evenly dispersed in the dryer and fully contacted with the hot air under the tumbling of the evenly distributed scrapers in the drum, which accelerates the heat and mass transfer of drying. During the drying process, the material is discharged to the star-shaped discharge valve in another section of the dryer under the action of the inclined scrapers and hot air.

Features and advantages:

The drum drying has a high degree of mechanization, large production capacity, and can operate continuously.

The structure is excellent and simple, the material runs smoothly through the drum resistance, and the operation is convenient.

Few failures, low maintenance costs, and low power consumption.

Wide range of application, good uniformity of product drying.

It can also achieve the purpose of sterilization and deodorization while drying.

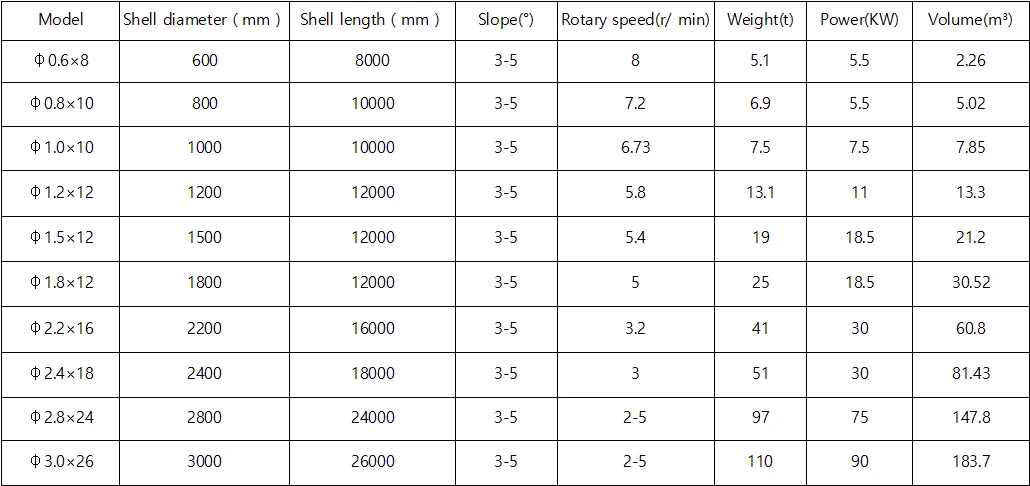

Technical Parameters: