High pressure suspension roller mill application range:

High-pressure suspension roller Raymond mill is suitable for crushing barite, limestone, ceramics, slag and other non-flammable and explosive materials with Mohs hardness not more than 9.3 and humidity below 6% for high-fine powder processing of more than 280 materials in mining, metallurgy, chemical industry, building materials and other industries. The finished product particle size is adjusted in the range of 80-425 mesh (the finest is 1000 mesh). The machine can produce 30-80 mesh coarse powder by adding special devices.

Working principle of high pressure suspension roller mill:

When the material to be ground enters the grinding chamber, it is scooped up by the shovel and sent to the grinding roller and grinding ring for grinding. The ground powder is brought into the analyzer with the circulating air of the blower. The qualified fine powder flows into the cyclone powder accumulator with the air and becomes the finished product. The large particles fall back to the re-grinding. The circulating air returns to the blower and repeats the above process. The remaining air enters the bag dust collector for purification.

Six major features of the high-pressure suspension roller mill:

1. Compared with other mills, the output is increased by 20-30% under the same power conditions, and the grinding force of the grinding roller on the material is increased by 800-1200Kg under the action of the high-pressure spring.

2. All mineral materials with Mohs hardness less than 9.3 can be processed and crushed.

3. The finished product has a wide range of particle sizes, with a coarse particle size of up to 0.613 mm (30 mesh), a general particle size of up to 0.033 mm (425 mesh), and a small number of materials can reach 0.013 mm (1000 mesh).

4. The dust removal effect fully meets the national dust emission standards.

5. The analyzer is easy to adjust.

6. The grinding device adopts overlapping multi-stage sealing with good sealing performance.

Equipment Technology:

Jaw crusher--bucket elevator--discharging valve--storage bin--electromagnetic vibrating feeder--speed reducer--host machine--blower--analyzer motor--fineness analyzer--dust collector--powder collector

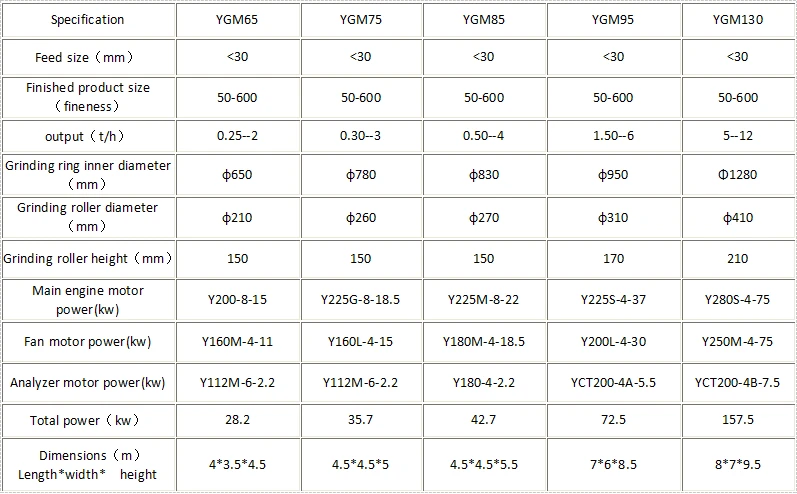

Technical parameters of high pressure suspension roller mill: