Structure and working principle:

Rotor: core component, equipped with plate hammer (hammer head), high-speed rotation to generate impact force.

Impact plate: multi-layer adjustable impact device, cooperate with the rotor to achieve multiple crushing.

Body: hydraulic or spring opening device is adopted for easy maintenance.

Drive system: motor + pulley (or direct drive).

After the material enters the crushing chamber, it is violently impacted by the plate hammer on the high-speed rotating rotor and thrown to the impact plate for secondary crushing; then the material repeatedly hits and rubs in the crushing chamber until it reaches the required particle size and is discharged from the discharge port.

Performance characteristics:

Features | explain |

|---|---|

Performance characteristics | The particle size of the material is fine (usually ≤3mm) and the crushing ratio is large (up to 50:1). |

Energy saving and low consumption | The impact crushing principle has low energy consumption and saves more than 30% energy compared with traditional hammer crushing. |

Highly adaptable | Can process medium hardness materials (limestone, coal gangue, gypsum, etc.), moisture content ≤8%. |

Easy maintenance | The impact plate is adjustable, and the hammer is made of high chromium alloy, which is wear-resistant and easy to replace. |

Good environmental protection | The closed structure reduces dust spillage, and some models are equipped with noise reduction design. |

Selection Guide:

1.Key Parameters

Feed particle size: ≤50mm (depending on the model).

Discharge particle size: 0-5mm (adjustable, fine crushing can reach 0-3mm).

Processing capacity: small machine (10-50t/h), large machine (100-300t/h).

Motor power: 55-400kW (matched according to production capacity).

2.Selection points

Material characteristics: hardness (Mohs hardness ≤6), humidity (high moisture content is prone to clogging).

Capacity requirements: match the production line output to avoid "big horse pulling a small cart".

Fineness requirements: select a multi-stage counter-cavity design when fine crushing is required.

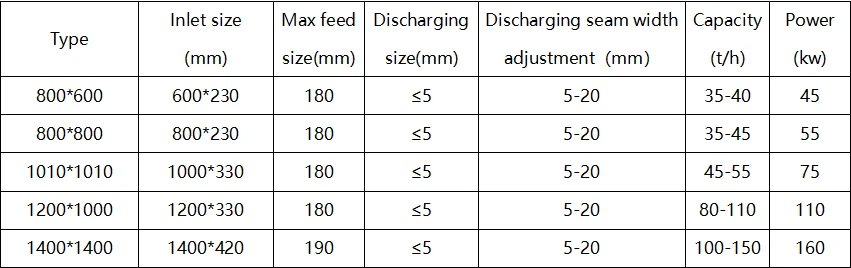

Technical Parameters: