Working principle:

1. Heat exchange and water evaporation

Sludge and feces enter the rotary drum through the spiral dispersing device and the feeding system, and come into direct or indirect contact with the high-temperature airflow (100°C–600°C), and the water evaporates rapidly. The heat source can be electric heating, steam, gas or biomass fuel, etc.

Adopt the downstream or countercurrent drying method: in the downstream, the high-temperature flue gas and the wet material enter in the same direction, which is suitable for initial rapid evaporation; in the countercurrent, the hot air enters from the discharge end, which is suitable for deep drying.

2. Mechanical stirring and anti-caking design

The drum is equipped with a lifting plate, a grate-type wing plate and a cleaning device, which forms a material curtain by repeatedly lifting and throwing the sludge to increase the thermal contact area.

The cleaning device cleans the adhered material in real time, and the built-in depolymerization mechanism breaks the clumps to avoid blockage and improve the drying efficiency.

A separate stirring and dispersing device is added to the sludge dryer on the basis of the single-drum dryer, and the stirring shaft is cooled by water to ensure the stability of the stirring shaft. The dryer adopts an integrated frame structure, which is easy to install.

The length of the dryer is between 8-10m. It uses high-temperature rapid drying to improve drying efficiency. In order to ensure heat utilization, a heat preservation device is usually added to the outside of the cylinder to reduce heat loss.

3. Phased drying process

Preheating area: The sludge is initially exposed to hot air to evaporate surface moisture.

Deep drying area: Through multiple heat exchanges, the moisture content is significantly reduced.

Cooling and discharge area: After drying, the sludge is cooled and discharged, and the exhaust gas is dusted and deodorized.

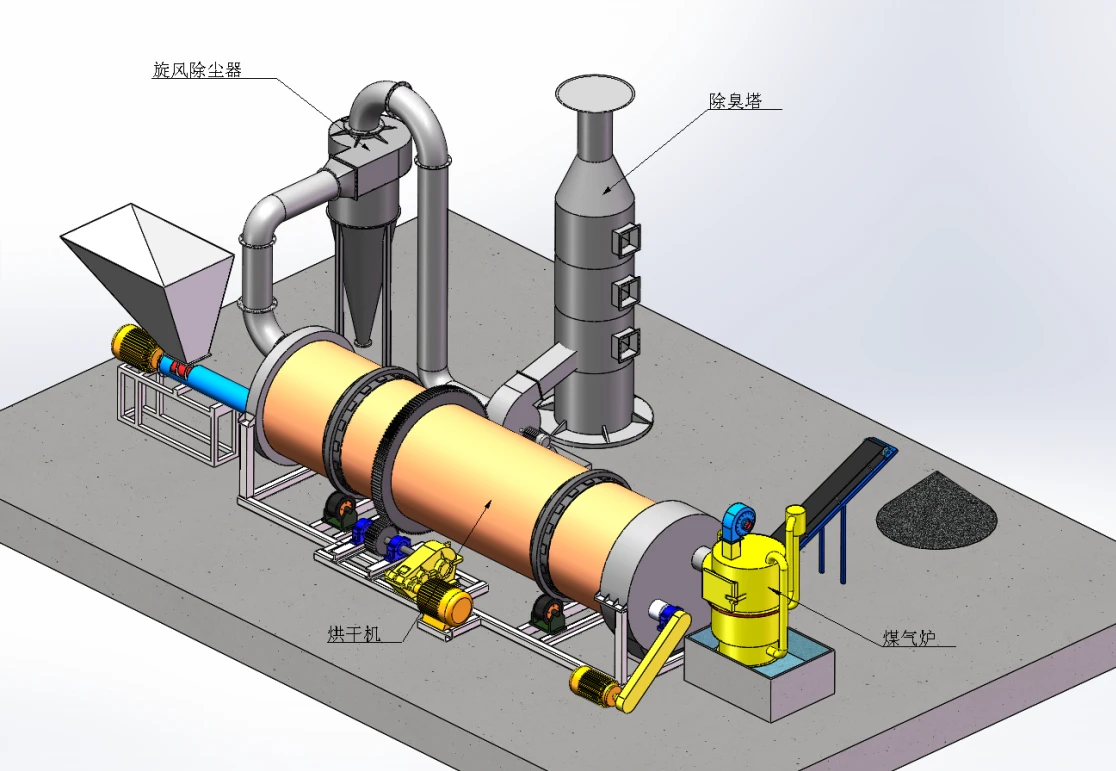

4. Dust removal stage

Sludge and feces dryers will generate a large amount of hot steam and organic gas during the drying process. When selecting dust removal, it is necessary to add 2-3 cyclone cooling weight dust removal, and then reduce the emission of micropowder particles through pulses, and finally add a deodorization tower to purify the gas to meet the emission standards.

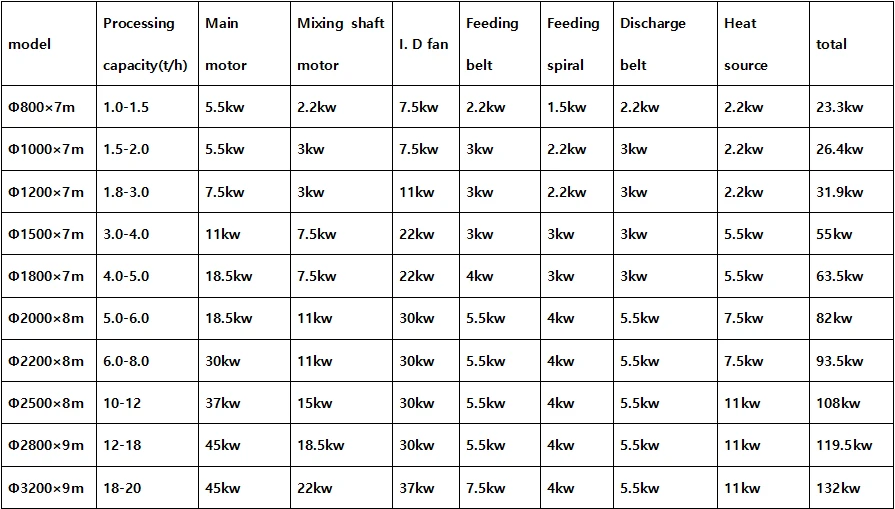

Technical Parameters: