Working Principle:

The motor is connected to the horizontal pinion shaft through a transmission mechanism. The shaft is provided with a pinion meshing with a large gear ring, and the outer gear is driven. It is a two-chamber, grid-type ball mill. The material is fed into the first chamber of the mill evenly through the feeding device through the hollow shaft of the feeder. The chamber has a stepped lining or a corrugated lining, and is filled with steel balls of different specifications. The centrifugal force generated by the rotation of the cylinder brings the steel balls to a certain height and then falls, which produces a heavy impact and grinding effect on the material. After the material is roughly ground in the first chamber, it enters the second chamber through a single-layer partition plate. The chamber is inlaid with a flat lining plate and contains steel balls to further grind the material. The powder is discharged through the discharge grate plate to complete the grinding operation.

Application range:

Energy-saving ball mills have a wide range of applications. They can be used to select various ash mineral materials such as gold, copper, iron, lead and zinc. They are also used in coal, power industry, cement industry, building materials, chemical industry and other industries. They are ball mill equipment with practical value.

Product features:

Energy-saving ball mills use rolling bearings instead of traditional sliding bearings. The starting current is small, saving 10-15% of power consumption, increasing production by about 25%, and saving 80% of lubricating oil; the cone-shaped energy-saving mill, in addition to the change of the bearing part, adopts a cone design at the discharge end. During operation, the steel balls of the material at the cone end are forced to naturally classify. The closer to the outlet, the smaller the diameter of the steel balls, which increases the repeated grinding effect and has obvious energy-saving effect.

(1) Reduce the power consumption of grinding. The power consumption per unit output is reduced by more than 10%.

(2) Save lubricating oil. Only less than 100 kilograms of lubricating oil are needed each year, and the oil saving amount is 80-90%.

(3) Increase the grinding body loading capacity. Compared with the ball mill of the same specification, the rolling bearing ball mill can increase the grinding body loading capacity by 15% to 20%, which is conducive to the increase of the output of the ball mill.

(4) The internal structure of the mill is optimized, the internal structure of the mill is improved, the cylinder volume is increased, the liner form and the discharge grate structure are optimized, which is conducive to improving the grinding efficiency of the cement ball mill and the control of product fineness.

(5) The large inner diameter double-row spherical roller bearing is adopted to increase the diameter of the feed and discharge ports, making them the same as the feed and discharge port diameter of the original sliding bearing, thereby increasing the processing capacity.

(6) The drum feeder is used instead of the original single spoon feeder, which reduces the impact on the motor, prolongs its service life, makes the cylinder run smoothly, and reduces energy consumption and noise.

(7) Standardized operation, strong versatility, convenient for later maintenance and repair.

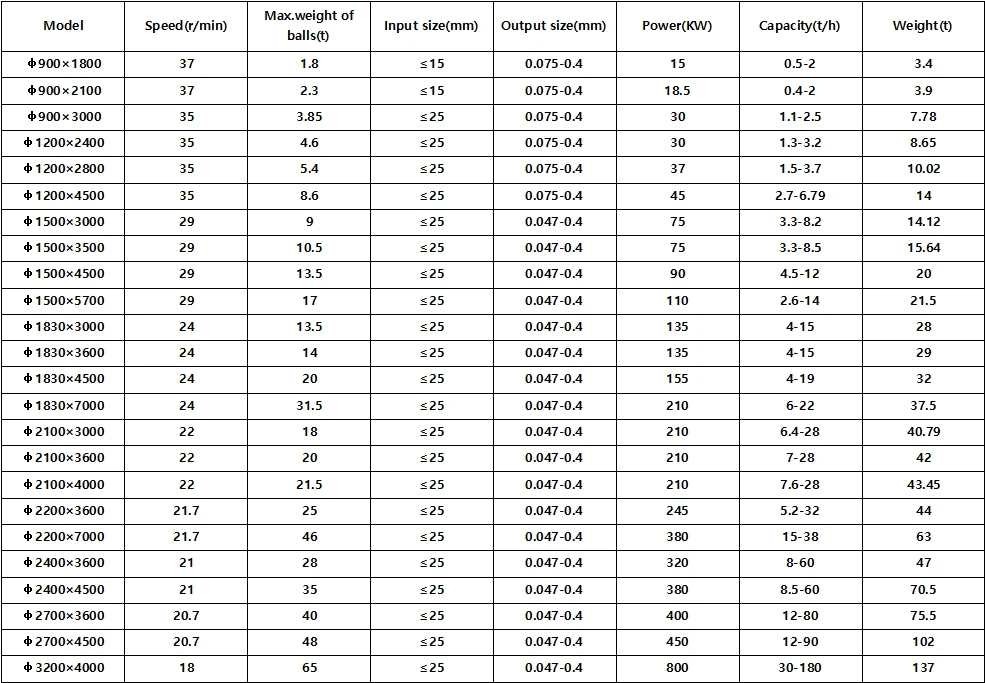

Technical Parameters: