Main functions of tailings dryer:

Reduction treatment: reduce the water content of tailings, reduce volume and weight, and facilitate transportation and stacking.

Environmental protection needs: prevent pollution caused by direct discharge of tailings slurry and avoid the risk of tailings dam collapse.

Resource recovery: dried tailings can be used for building materials (such as bricks, cement), roadbed filling or secondary mineral processing.

Safe storage: dried tailings are more stable and reduce leachate and dust problems.

Working principle:

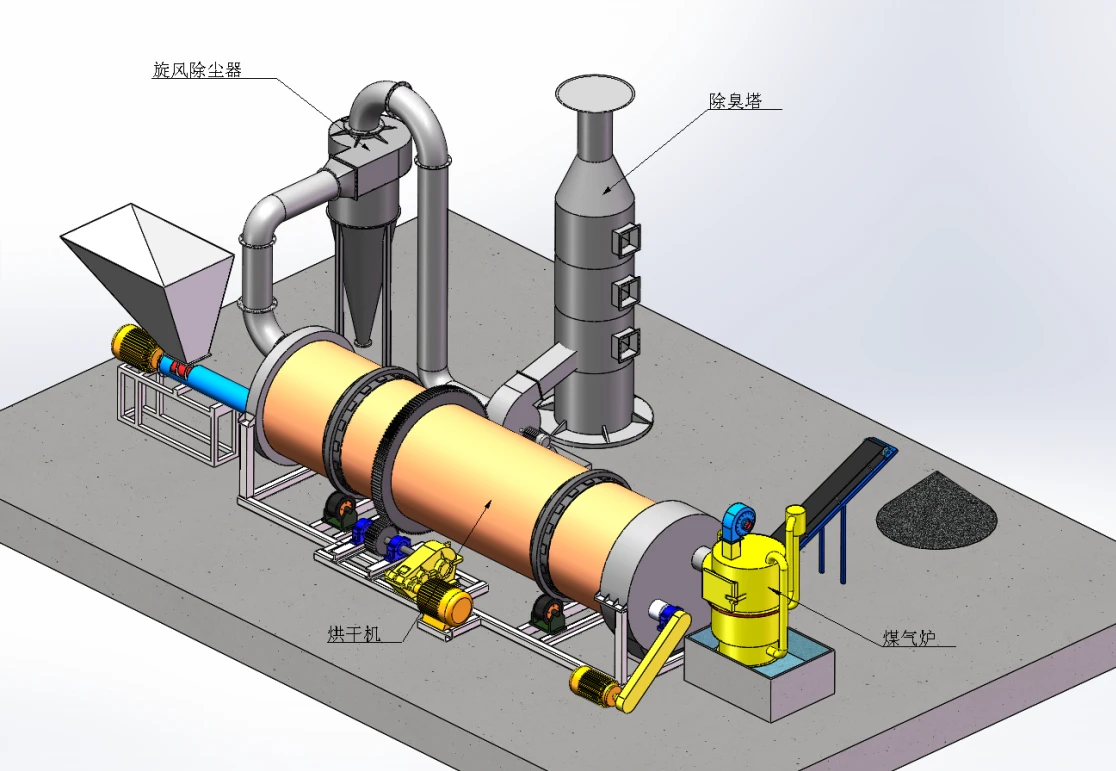

Structure: long drum with tilted rotation and material lifting plate inside.

Heat source: coal, gas, steam or waste heat (such as waste heat from power plants).

Process: wet tailings are in countercurrent/cocurrent contact with hot air, and the water evaporates and is discharged from the discharge port.

Key factors for selection:

1. Tailings characteristics: initial moisture content (usually 30%~70%), particle size, viscosity, and corrosiveness.

2. Capacity requirements: small (several tons per day) to large (thousands of tons per day).

3. Heat source selection: adapt to local conditions and give priority to the use of industrial waste heat or low-cost energy.

4. Environmental protection requirements: equipped with dust removal (bag/cyclone dust removal) and desulfurization equipment to meet emission standards.

5. Drying target: the final moisture content (such as below 15%) determines the drying temperature and duration.

Technical advantages:

Energy-saving design: multi-stage waste heat recovery and insulation layer to reduce heat loss.

Automation control: temperature and humidity sensors are linked to adjust to avoid over-drying or energy waste.

Corrosion-resistant materials: lined with stainless steel or anti-corrosion coating to extend equipment life.

Application cases:

Metal mine tailings: such as iron tailings are dried to make bricks or backfill goafs.

Phosphogypsum tailings: used as cement retarder after drying.

Gold tailings: secondary extraction of valuable metals after dehydration.

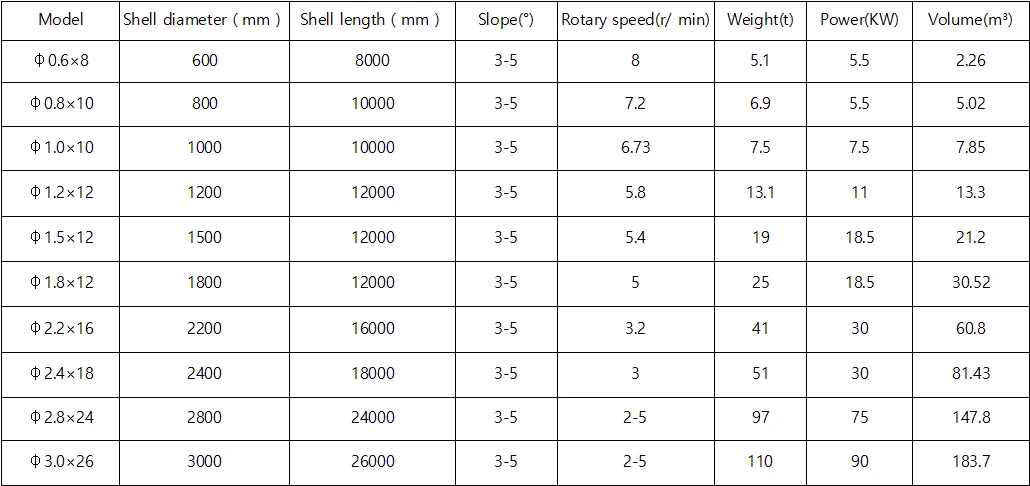

Technical Parameters: