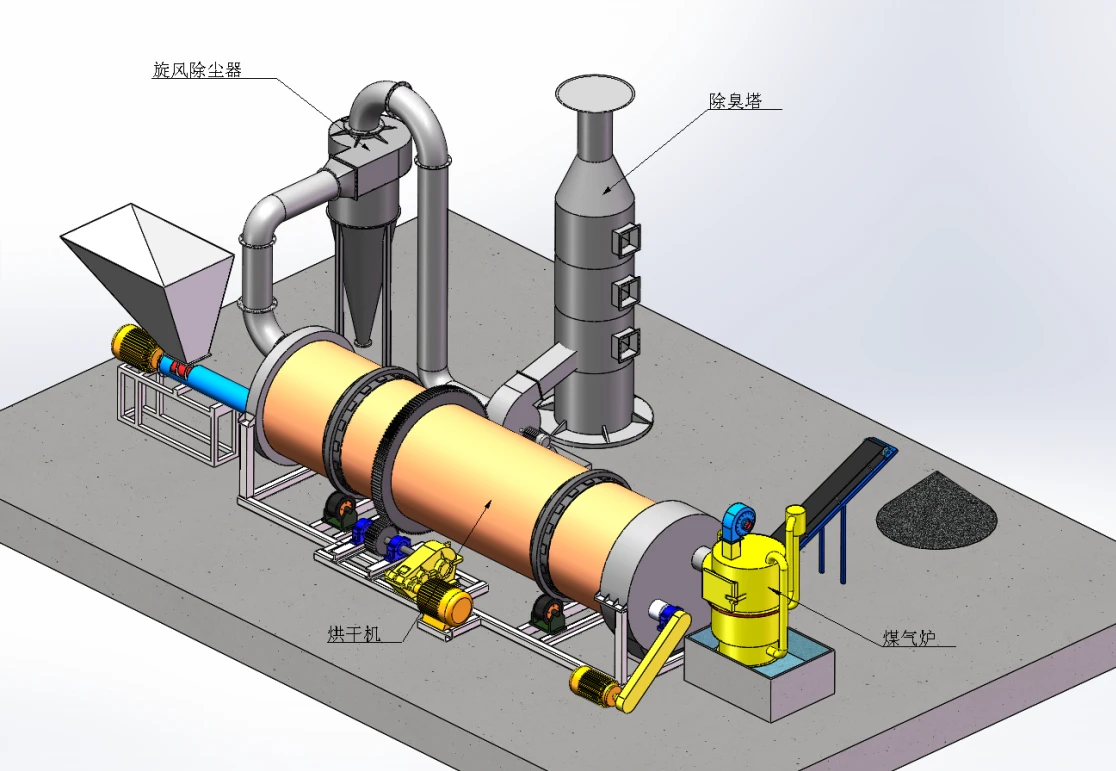

Working Principle:

The sludge enters the guide plate inside the sludge dryer through the chute from the feeder. As the cylinder rotates, the sludge is guided to the inclined lifting plate and lifted to the center of the cylinder. It gradually falls to form a material curtain, and the high-temperature airflow passes through it, preheating the sludge and evaporating part of the water. When the sludge falls and moves to the movable grate-shaped wing plate, the material is mixed with the preheated grate-shaped wing plate, transferring heat to the material, causing part of the water to evaporate. At the same time, the wing plate carries the material to be lifted and scattered, and repeats many times, and the material and the hot air flow undergo convection and contact heat exchange. At the same time, the cleaning device buried in the material also slides down along the inner side of the arc-shaped lifting plate to clean up the material adhering to the inner wall of the lifting plate. After the cleaning device rotates through the vertical line with the cylinder, it drags on the back of the arc-shaped lifting plate to clean up the material adhering to the outer wall of the lifting plate. As the cylinder of the sludge dryer rotates continuously, part of the water evaporates and the sludge is further dried. At the same time, the cleaning device also breaks up the sludge balls, which increases the drying speed. After drying, the sludge becomes loose material with low moisture content and is discharged from the discharge port of the sludge dryer.

Outstanding advantages:

1. It can process sludge with a water content of 90% and has strong adaptability;

2. There is a lifting plate in the drying cylinder, which can make the material heated evenly and dried fully;

3. The dryer has a high degree of automation and adopts an advanced fuzzy control system to achieve automatic control of product quality.

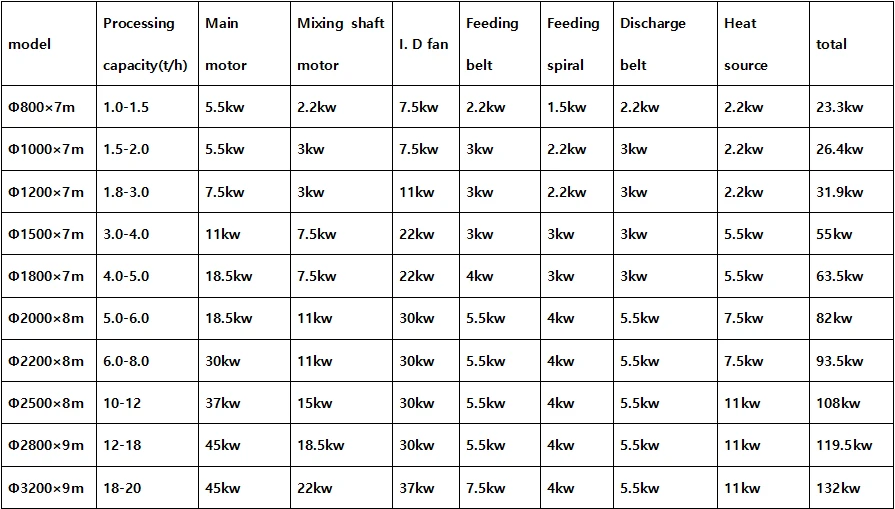

Technical Parameters: