Core grinding principle:

1. Crushing mechanism

Impact crushing: Steel balls/ceramic balls fall from a height and hit quartz particles (suitable for coarse grinding).

Grinding erosion: Rolling friction between balls produces shear force (suitable for fine grinding).

2. Classification: The rotation of the cylinder drives the particles to be separated by particle size, and the fine particles are discharged from the discharging grate plate.

Key Components Description:

| Part | Material/Parameters | Special Requests |

|---|---|---|

Cylinder | 16Mn steel plate (thickness 20-50mm) | Lined with rubber/high alumina ceramic (anti-SiO2 pollution) |

Grinding media | High chrome steel ball (Φ30-100mm) or silica ball | Hardness ≥HRC58, filling rate 30%-45% |

Liner | Corrugated lining (to increase the ball height) | Wear-resistant layer thickness ≥15mm |

Drivetrain | Edge drive (high power) or center drive (precision) | The torque of the reducer needs to reserve 20% margin |

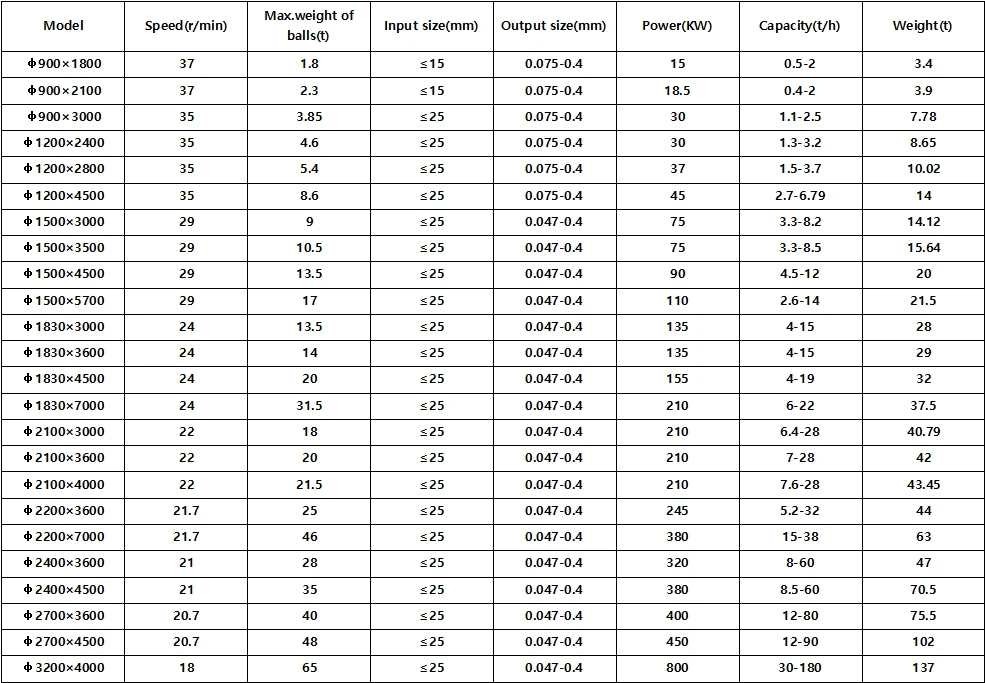

Technical Parameters: