Working principle:

The cylinder is driven to rotate by the motor through the reducer and the surrounding large gears or by the low-speed synchronous motor directly through the surrounding large gears. The cylinder is equipped with appropriate grinding media-steel rods. Under the action of centrifugal force and friction, the grinding media is lifted to a certain height and falls in a state of throwing or leaking. The ground material continuously enters the cylinder from the feed port, is crushed by the moving grinding media, and is discharged out of the machine through overflow and continuous feeding force for the next process.

Rod mills are classified into three categories:

1. Overflow rod mill

Overflow rod mill is more commonly used, and the product particle size is finer than the other two types. It is generally used to grind the crushed product and then supply it to the ball mill. The product particle size is 2-0.5 mm.

2. End peripheral discharge rod mill

End peripheral discharge rod mill is generally used for dry grinding, and the product particle size is coarser. This type of rod mill can also be used for wet grinding. The use of peripheral discharge rod mill can obtain high gradient and good flow rate. The product particle size is 5-2 mm.

3. Center peripheral discharge rod mill

Center peripheral discharge rod mill can be used for wet and dry grinding. The product particle size is coarser. The material is fed from both ends of the rod mill. The grinding process is short and it is discharged quickly. The gradient is high and the product is too fine sand. This type of rod mill is mainly used in the aggregate industry to produce sand and gravel.

Product features:

1. Power saving

Compared with the old equipment, it saves more than 40% of power. The product particle size is more uniform, with less coarse particles and ore mud. Compared with the particle size characteristics of the rod mill product and the ball mill product, the particle size characteristic curve of the rod mill working in open circuit is almost the same as that of the ball mill working in closed circuit.

2. Uniform discharge and high output

Adopting advanced controllable feeding and discharging rod mill technology, combined with the actual user's grinding materials, suitable grinding bodies are used, and the surface contact of the traditional ball mill is changed to line contact, so that the discharge particle size of Zhongjia Energy Saving Rod Mill is uniform and the output is high, which is suitable for ores of different hardness (Mohs hardness 5.5~12).

3. Feed particle size tolerance

The crushing ratio of the rod mill is 15:1 to 20:1. The conventional crushing and grinding process of most foreign beneficiation plants is composed of crusher, rod mill and ball mill. There are not many rod mills in my country's beneficiation plants. The feed particle size of the ball mill is high, resulting in large energy consumption, grinding medium consumption, and liner consumption. Because the grinding rods of the rod mill are in line contact, large materials are ground first, which has a selective grinding effect. Therefore, the product particle size range is narrow, the product particle size is uniform, there is less over-crushing, and the grinding efficiency is higher.

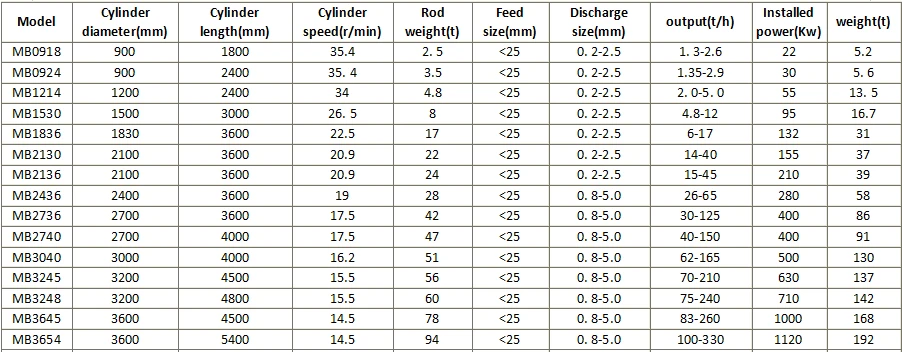

Technical Parameters: