Main structure of calcium aluminate powder rotary kiln:

(1) Kiln system

Cylinder: welded with high-temperature resistant steel plate (Q345R or 310S stainless steel), lined with high-alumina bricks or corundum bricks, with a temperature resistance of 1350~1500℃.

Tilt angle: 2.5~4°, rotation speed 0.8~2.5 rpm, to ensure uniform calcination of materials.

Length: usually 40~80m, designed according to production capacity requirements.

(2) Combustion system

Fuel type: natural gas, coal gas, diesel, pulverized coal (low ash coal required).

Burner: multi-channel low-nitrogen burner is used to accurately control the flame shape and temperature distribution.

(3) Preheating and cooling system**

Preheater (optional): five-stage cyclone preheater can increase thermal efficiency by more than 20%.

Cooler: single-cylinder or grate cooler is mostly used to quickly cool the product to below 100℃.

(4) Dust removal and environmental protection system

High-efficiency bag dust removal: dust emission ≤20mg/m³.

SCR denitrification + wet desulfurization (optional): meet ultra-low emission requirements (NOx≤100mg/m³).

Working principle of calcium aluminate powder rotary kiln:

1. Raw material preparation: bauxite (Al₂O₃≥50%) and limestone (CaO≥52%) are mixed in proportion (usually CaO/Al₂O₃=1~1.5).

2. High temperature calcination: solid phase reaction occurs at 1350~1500℃

3. Cooling and crushing: After the kiln clinker is cooled, it is ground to 200~400 mesh (calcium aluminate powder finished product) by ball mill.

Core advantages of calcium aluminate powder rotary kiln:

(1) High product purity

Al₂O₃ content can reach 50~80%, and the mineral phase (CA, C₁₂A₇) is controllable.

Low impurities: Fe₂O₃≤1.5%, SiO₂≤3% (better than electric melting method).

(2) Energy saving and high efficiency

The five-stage preheater can reduce the heat consumption to 850~1000 kcal/kg clinker.

Waste heat power generation (optional): Use kiln tail exhaust gas to generate electricity and reduce production costs.

(3) Environmental protection standards

Ultra-low emissions: dust ≤20mg/m³, NOx ≤100mg/m³ (GB 30485-2013).

No wastewater generation: pure dry process.

(4) Automatic control

The DCS system automatically adjusts the temperature, air volume, and feed rate, and the product stability is ±1%.

Online composition analyzers (such as XRF) monitor the Al₂O₃/CaO ratio in real time.

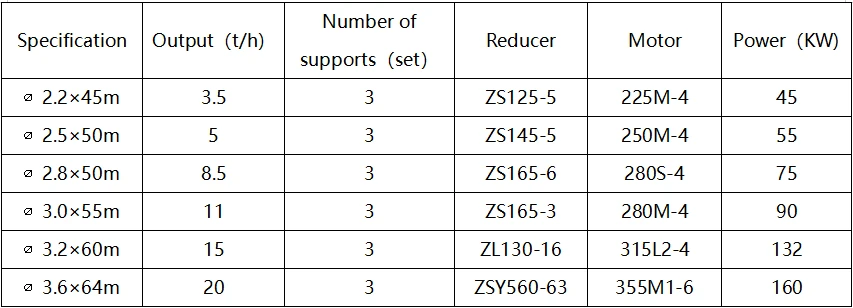

Main technical parameters:

Application fields of calcium aluminate powder:

Refractory materials: castables, spray coating binders (CA-70, CA-80 series).

Wastewater treatment: high-efficiency defluoridation agent (C₁₂A₇ has the highest activity).

Building materials: sulphoaluminate cement accelerator.

Metallurgy: ladle refining slag regulator.