Introduction :

Activated carbon is also called activated carbon black. It is amorphous carbon in black powder or granular form. In addition to carbon, the main components of activated carbon also include oxygen, hydrogen and other elements. In terms of structure, activated carbon is a porous carbon with low bulk density and large specific surface area because the microcrystalline carbon is irregularly arranged and there are pores between the cross-links. Activated carbon is irregularly arranged and has pores between the cross-links. Activated carbon is a porous carbon with low bulk density and large specific surface area.

Applications of activated carbon:

1. Decolorization and filtration to decolorize colored liquids.

2. Absorb various gases and vapors.

3. For chromatographic analysis.

4. Reducing agent for measuring methanol, tin and silicon.

5. Granular materials can be used as catalyst carriers.

Uses and application scope of activated carbon Raymond mill:

It is mainly suitable for grinding and crushing conventional materials, such as barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, manganese ore, iron ore, copper ore, chromium ore, refractory materials, thermal insulation materials, coal coke, coal powder, carbon black, clay, bone meal, titanium dioxide, iron oxide, quartz and other non-flammable and explosive materials with Mohs hardness not more than 7 and humidity below 6%. It is used in the high-fine powder processing of more than 300 materials in the mining, chemical, construction and other industries. The particle size of the finished product can be adjusted arbitrarily within the range of 80-325 mesh, and some materials can reach 600 mesh.

Structural features of activated carbon Raymond mill:

1. Raymond mill has a three-dimensional structure, small footprint, strong completeness, and an independent production system from block material to finished powder.

2. The finished powder has uniform fineness and a screening rate of 99%, which is difficult for other grinding equipment to have.

3. The main transmission device of the grinding mill adopts a closed gear box and pulley, which has stable transmission and reliable operation.

4. The important parts of the Raymond mill are made of high-quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

5. The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation and convenient maintenance.

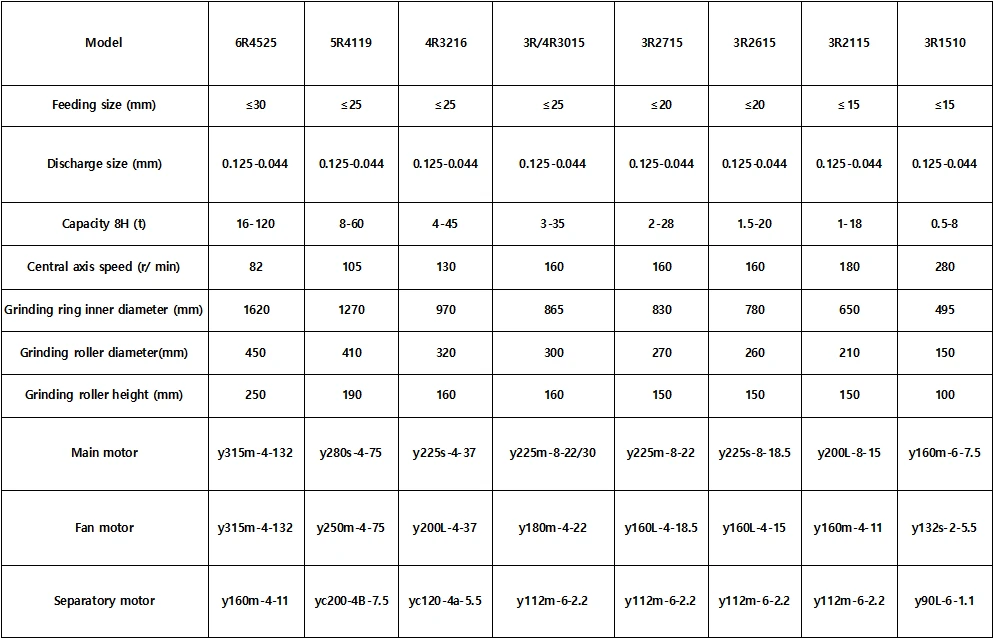

Activated carbon Raymond mill technical parameters: