Introduction to solid waste and hazardous waste rotary kiln:

Solid waste and hazardous waste rotary kilns have many advantages such as wide adaptability, stable and reliable operation, convenient management and operation, and simple equipment maintenance for complex industrial waste and medical waste. Therefore, they are widely used in the incineration and disposal of hazardous waste internationally. Incineration is a relatively reliable and effective means to achieve harmlessness, reduction and resource utilization of solid and hazardous waste.

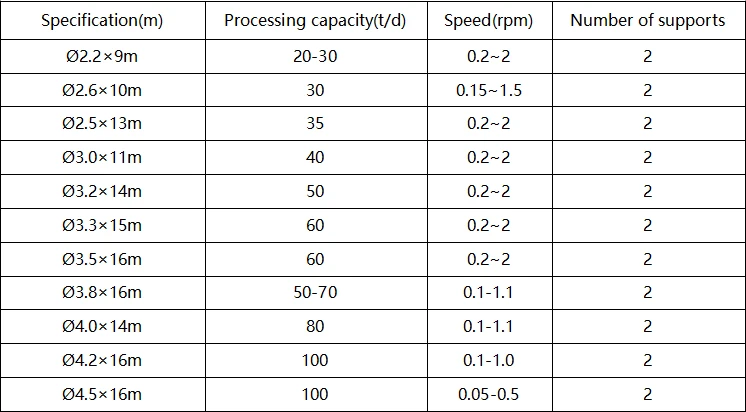

Capacity: 10-120t/d (specifically depends on the moisture content of the material)

Specifications: Ø2.2×9m-Ø4.5×16m

Calcination temperature: 850-1200℃

Application range: used for various solid and hazardous waste disposal in medical, industrial comprehensive solid and hazardous waste, petroleum, chemical and other industries.

Working Principle:

The rotary kiln is equipped with a pusher at the feed port to ensure continuous feeding. The outlet temperature of the rotary kiln is 800-850℃. After the flue gas enters the secondary combustion chamber, secondary air is sprayed tangentially around the secondary combustion chamber, so that a strong vortex field is formed in the secondary combustion chamber, and the combustible components in the flue gas can be fully burned. At the same time, the secondary combustion chamber adopts a unique structural design to make the secondary combustion chamber also have a cyclone dust removal function. The outlet flue gas temperature of the secondary combustion chamber is greater than 1100℃, and the flue gas stays in the high temperature zone for more than 2 seconds, ensuring that the harmful components in the flue gas, including dioxins, are completely decomposed and meet the requirements for the incineration of hazardous waste. Solid (hazardous) waste is fed into the rotary kiln body through the feeding mechanism for high-temperature incineration. After high-temperature incineration, the material is incinerated into high-temperature flue gas and ash. The speed of the rotary kiln can be adjusted. Maintaining a stable slag layer of about 50mm thick can protect the refractory layer. Its operating temperature should be controlled at about 850℃. High-temperature flue gas and ash enter the secondary combustion chamber from the kiln tail, and the incineration ash enters the slag discharger from the kiln tail and is regularly sent to the stabilization/solidification workshop for treatment.

Outstanding advantages:

At present, the comprehensive solid (hazardous) waste incineration system is mainly based on rotary kiln + secondary combustion chamber incineration technology, using advanced and mature processes at home and abroad, and determining the process route and equipment configuration according to the characteristics of the processed materials provided by the owner, providing customized full-process services for the owner to ensure that pollutant emissions meet the current standards.

From overall project planning to detailed process formula, process design, equipment design and manufacturing, engineering installation, commissioning, etc., it provides complete full-industry chain services and has complete solid (hazardous) waste treatment system solutions.

1. Provide complete services for the entire industry chain and have complete solutions for solid (hazardous) waste treatment systems;

2. Advantages of hazardous waste products: high-temperature incineration to achieve harmlessness, reduction, stabilization, and resource utilization;

3. Advantages of various solid waste products such as sludge: resource disposal, waste utilization, and production of building ceramsite;

4. The furnace has a large heat load and the materials are thoroughly incinerated, which is sufficient to cope with the complete incineration of a large amount of hazardous waste.

Technical Parameters: