Process flow of ceramsite sand rotary kiln

1. Crushing and grinding: After secondary crushing by jaw crusher and hammer crusher, the raw material enters the ball mill for grinding. Generally, a ball mill for drying and grinding is selected, and an efficient powder selector is used to form a closed-loop system to increase the grinding output. The hot air for drying can use the exhaust gas of the rotary kiln to improve the utilization of waste heat.

2. Ball making: The ground raw material powder is stored in the material tank and enters the ball forming disk through the metering screw. During the rotation of the ball forming disk, various specifications of balls can be made. After the balls leave the ball forming disk, they enter the drum screen through the belt conveyor. The qualified ones enter the rotary kiln for calcination, and the unqualified ones return to continue granulation.

3. Calcination: The qualified balls enter the rotary kiln with a certain slope. After a high temperature of about 1360℃ and a sintering time of 0.5-2 hours, the balls are calcined into ceramsite sand with high strength.

4. Finished product cooling: The cooling of ceramsite sand generally adopts a drum cooler, which is simple and reliable. The secondary air of the cooler can be fully fed into the kiln, and the temperature of the cooled ceramsite sand is ﹤60℃. After cooling, it enters the drum screen and can be divided into multiple particle size grades as required.

Type I 0.45-0.9mm (20-40 mesh) high strength medium density

Type II 0.9-1.25mm (16-20 mesh) high strength medium density

Type III 1.0-1.7mm (12-18 mesh) high strength medium density

Large pieces return to the raw material crushing process.

Petroleum proppant rotary kiln equipment introduction:

1. Equipment features

Simple structure: It has the characteristics of high unit volume, long kiln life, high operation rate, stable operation, high heat transfer efficiency, and low heat consumption.

Intelligent control: It is equipped with automatic temperature control and over-temperature alarm system, and adopts secondary air intake waste heat utilization technology to improve energy utilization.

Sealing technology: It adopts advanced kiln head and kiln tail sealing devices to ensure stable operation and high output.

2. Structure and working principle

Main components: including rotary cylinder, support device, wheel support device, kiln head and kiln tail sealing device, coal injection pipe device, etc.

Working principle: The kiln body has a certain slope (usually 3%-4%), the material enters from the kiln tail, is heated and calcined during the rotation process, and finally discharged from the kiln head.

Transmission mode: It adopts gear transmission or variable frequency motor drive to ensure stable operation.

Performance requirements of petroleum proppants:

1. The proppant must have sufficient compressive strength and wear resistance, be able to withstand the strong pressure and friction during injection, and effectively support artificial fractures.

2. The relative density of proppant particles should be low to facilitate pumping into the well.

3. The proppant particles do not react chemically with the fracturing fluid and reservoir fluid at a temperature of 200 degrees, and the maximum allowable acid solubility should be less than 7%.

4. Petroleum proppant ceramsite is divided into 0.09-0.3mm ceramsite according to the particle size range; 0.3-0.5mm small particle ceramsite, 0.5-0.9 medium particle ceramsite and 1.25-0.9 large particle ceramsite; according to the anti-crushing ability, it is divided into four types: 52Mpa, 69Mpa, 86Mpa, and 102Mpa. Ceramsites of different strength levels can be selected according to the depth of the oil well and the calculated closing pressure.

The main raw materials of bauxite ceramsite sand are: bauxite (raw ore powder Al2O3 ≥ 70%), manganese powder (low grade below 50%), magnesium oxide, iron oxide recycling, etc.

The Al2O3 content of medium-strength ceramsite is 44%-77%, and the Al2O3 content of high-strength ceramsite is between 85%-90%.

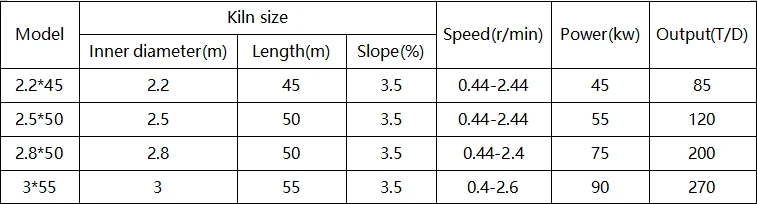

Technical parameters: