Introduction to Gypsum Calcination Kiln:

Gypsum is a monoclinic mineral, the main component of which is CaSO4 hydrate. Natural dihydrate gypsum, also known as soft gypsum or raw gypsum, is calcium sulfate (CaSO4·2H2O) containing two crystal waters. Natural dihydrate gypsum can be used to make gypsum of various properties.

Gypsum rotary kiln calcination of natural gypsum generally uses calcined particles and then grinds them into powder. Natural gypsum generally uses indirect heating, low-temperature slow burning as the main heat source, and coal as the heat source.

Gypsum rotary kiln is also used for the calcination of desulfurized gypsum and phosphogypsum. It adopts the principle of high-temperature fast burning, and generally uses natural gas as the main heat source. The main factors affecting desulfurized gypsum are fly ash and limestone. One ton of desulfurized gypsum can calcine about 770kg of building gypsum.

The gypsum rotary kiln cylinder is generally made of Q235B or Q345R steel plate, lined with heat-resistant steel or refractory materials (working temperature 150-400℃)

Special design: a lifting plate system is set to promote heat exchange

Tilt angle: 3-5°, speed 1-4rpm adjustable

Length: usually 25-65m (depending on production capacity requirements)

Working principle of gypsum rotary kiln:

1. Raw material pretreatment:

Natural gypsum is crushed to 20-40mm

Industrial by-product gypsum (such as phosphogypsum) needs to be washed and purified first

2. Calcination process:

Low temperature section (120-160℃): remove free water

Medium temperature section (160-180℃): dihydrate gypsum → hemihydrate gypsum

CaSO₄·2H₂O → CaSO₄·0.5H₂O + 1.5H₂O↑

High temperature section (180-400℃): generate anhydrous gypsum (as needed)

3. Cooling and discharging:

Discharging temperature ≤80℃

Obtain products of different fineness through vibration screening

Core advantages of gypsum rotary kiln:

(1) Stable product quality**

Semi-hydrated gypsum conversion rate ≥ 95%

Adjustable setting time (initial setting 4-8 minutes, final setting 8-15 minutes)

Flexural strength ≥ 3.5MPa (in line with GB/T 9776-2022 standard)

(2) Energy saving and environmental protection

Heat consumption ≤ 350,000 kcal/t gypsum powder (15% energy saving compared with boiling furnace)

100% industrial by-product gypsum (such as phosphogypsum, desulfurized gypsum) can be used

Fully enclosed design, dust emission ≤ 20mg/m³

(3) High degree of automation**

DCS control system realizes:

Precise temperature control (±5℃)

Automatic speed adjustment

Fault self-diagnosis

(4) Strong adaptability

Can process natural gypsum and various industrial by-product gypsum

By adjusting process parameters, it can produce:

Building gypsum powder (β type)

High-strength gypsum (α type)

Anhydrous gypsum

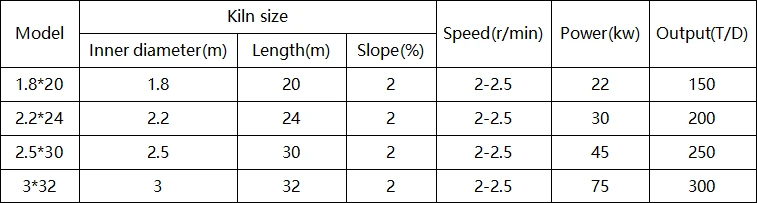

Gypsum calcining kiln parameters: