Chemical rotary kiln:

During the preparation of the catalyst, a certain amount of water and other organic matter or impurities often remain, which will poison the catalyst and affect the effect of the catalytic reaction. These impurities and water can be removed by calcining the catalyst in a rotary kiln, thereby improving the purity of the catalyst. Calcination can promote the crystal growth inside the catalyst and improve the stability and activity of the catalyst. In addition, the catalyst calcination rotary kiln can also increase the pore structure and specific surface area of the catalyst, increase the opportunity for the catalyst to contact the reactants, and thus increase the reaction rate. Calcination is a key step in the catalyst preparation process. The main purpose is to remove organic matter, water and other impurities in the catalyst through heating treatment in the catalyst calcination rotary kiln, thereby improving the purity of the catalyst; at the same time, calcination can also fully disperse and transform the active components of the catalyst to form the required crystal structure, thereby improving the activity and selectivity of the catalyst. The catalyst calcination rotary kiln is a steel thin-walled cylinder with a slope of 1%-6% installed on a support device. Due to the inclined installation of the cylinder, the material in the kiln moves axially while turning in the circumferential direction. Thus, it slowly flows through the entire cylinder, and after complex physical and chemical changes, it completes the dehydration and decarbonization process. It is discharged from its lower end (also known as the tail end of the kiln) and enters the cooling system. The fuel is sprayed from its lower end into the high-temperature area of the kiln for combustion. Under the action of natural or mechanical ventilation at the kiln head, the hot flue gas and the material flow through the entire kiln in reverse, and are discharged into the atmosphere through the chimney after dust collection. The catalyst rotary roasting furnace is a high-temperature oxidation equipment that can treat the catalyst at high temperature to improve its stability and activity. The equipment injects the catalyst into the rotating cylinder, and then introduces high-temperature oxygen into the rotating cylinder, so that the catalyst is treated under high-temperature oxidation conditions. In this process, the unstable substances on the surface of the catalyst will be oxidized and removed, thereby improving the stability of the catalyst.

The catalyst roasting rotary kiln removes organic matter, moisture and other impurities in the catalyst through high-temperature heating, thereby improving the activity and stability of the catalyst. During the roasting process, the catalyst needs to be heated in a specific atmosphere (such as air, nitrogen or reducing atmosphere), and the temperature is usually between 400℃ and 700℃. During this process, impurities such as organic matter and water on the catalyst surface are oxidized or decomposed into gases and volatile substances, which are desorbed and removed from the catalyst surface. At the same time, the calcination process can also promote the crystal growth and pore structure formation inside the catalyst.

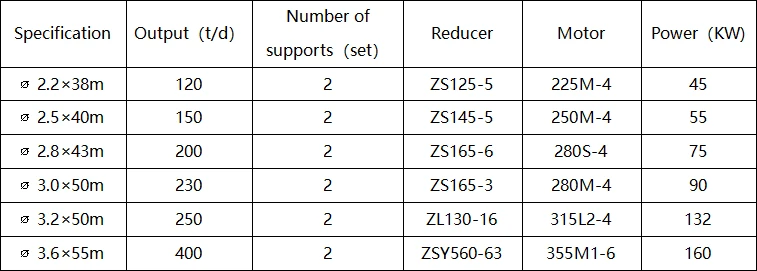

Chemical rotary kilnTechnical Parameters: