Application:

This machine is widely used in the fine grinding processing of more than 300 kinds of materials with Mohs hardness below 9.3 and humidity below 6% in non-flammable and explosive minerals, construction, chemical industry, fertilizer and other industries, such as quartz, recrystallization, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, phosphate rock, refractory materials, etc. The finished product particle size is in the range of 60-325 mesh (0.125 mm - 0.044 mm). The fineness of a small part of the material can reach 1000 mesh (0.013 mm) as needed.

Structural composition:

The whole structure of bentonite mill is composed of main machine, analyzer, pipeline device, blower. It can be equipped with crusher, elevator, electromagnetic vibrating feeder, electronically controlled motor, etc. according to user needs.

Performance characteristics:

1. The bentonite mill occupies a small area and has strong complete set. It can form an independent production system from block crushing to finished product packaging.

2. The particle size screening rate of the finished product ground by Raymond mill can reach more than 99%, which is beyond the reach of other mills.

3. The electromagnetic vibrating feeder is used to feed evenly, easy to adjust, small in size, light in weight, fuel-saving and electricity-saving, and easy to maintain.

4. The electrical centralized control selection is advanced, and unmanned operation can be achieved in the main engine room.

5. The main engine transmission device adopts a closed reducer, which has stable transmission, reliable operation, and no oil leakage.

6. The main engine blade frame is always in contact with the material during operation, so the blade frame consists of upper and lower parts. After the lower seat is worn, the connecting bolts can be removed and replaced.

Working Principle:

After the material is crushed to the required particle size, the elevator will send the material to the storage hopper, and then the vibrating feeder will evenly and continuously send the material into the main grinding chamber. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring. The scraper scoops up the material and sends it between the grinding roller and the grinding ring. The grinding roller rolls to achieve the purpose of crushing. The fine powder after grinding is brought into the analyzer for sorting with the circulating air of the blower. The material with too coarse fineness falls back to the re-grinding, and the qualified fine powder enters the finished product cyclone powder collector with the air flow and is discharged through the powder outlet pipe to become the finished product. In the grinding chamber, there is a certain amount of moisture in the material to be ground, heat is generated during grinding, water vapor evaporates, and the interfaces of the pipelines of the whole machine are not tight, so the external gas is sucked in, which increases the circulating air pressure, ensuring that the mill works under negative pressure. The increased air flow is discharged into the dust collector through the residual air duct and discharged into the atmosphere after purification.

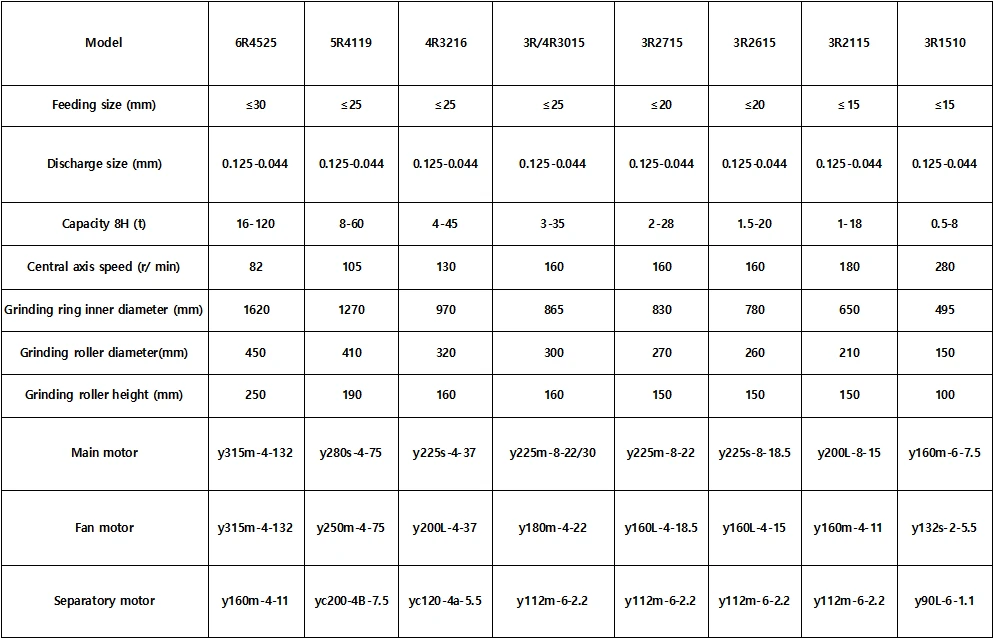

Technical Parameters: